MRO Technology

A proven model that aligns people with deep category expertise, center-led process, and full-scale digital supply chain management (DSCM) technology…

Home » Supply Chain Services » MRO Supply Chain As-a-Service

Take advantage of SDI’s 50+ years of market intelligence, deep knowledge of MRO and manufacturing processes, and purpose-built Digital Supply Chain Management platform, ZEUS, in a full end-to-end program that we call Enterprise MRO…or as-a-service.

Whether you implement an Enterprise MRO solution or MRO-as-a-Service, SDI sets you on a journey towards process excellence in an easier, step-by-step approach that’s less disruptive to your operations. It’s about flexibility and speed-to-result – bringing service, processes, systems, MRO-specific technology and expertise together into one ecosystem. This means more agile and adaptable business outcomes – to better serve your customers.

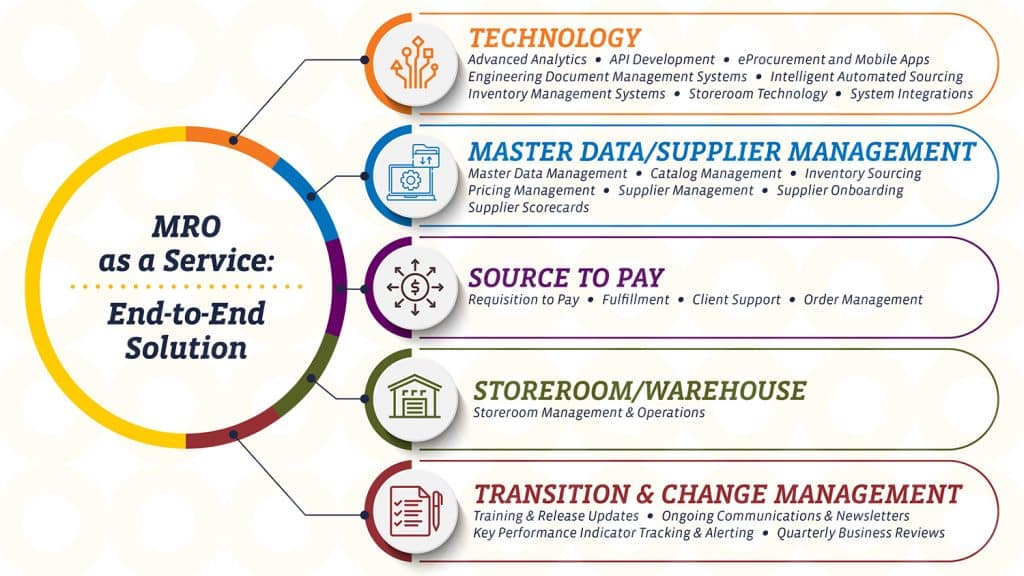

SDI connects all the components of the MRO supply chain, so no matter where you plug in, you can always expand your program to receive the full value of a more connected enterprise.

Plug in to any component of the value chain with MRO as-a-Service and immediately impact your key business value levers.

A proven model that aligns people with deep category expertise, center-led process, and full-scale digital supply chain management (DSCM) technology…

The latest technologies and processes for data collection, warehousing, and management for requisitioning material and other supply transactions…

Beyond onboarding, active supplier performance management to ensure real-time supply chain visibility that translates into real-world results…

Full life-cycle requisition to payment…and back again, capturing data-driven insights to get more spend under contract and spend where it makes the most impact…

Full life-cycle requisition to payment…and back again, capturing data-driven insights to get more spend under contract and spend where it makes the most impact…

A proven Project Management methodology combined with Lean and Six Sigma philosophy and practices that have brought about dramatic change – with dramatic results…