Master Data Management

Home » Supply Chain Services » Master Data Management

About Master Data Management

Comprehensive Maintenance, Repair, and Operations (MRO) Data Cleansing

Our solutions incorporate the latest technologies for data collection, warehousing, and management. We start with clean data, including controlled data maintenance for all description changes and new parts, to ensure information integrity. Data cleansing is the cornerstone of effective data management.

As a result of master data cleansing, our clients have experienced:

- 5-8% uptime improvements

- 20-30% reduced inventory

- 8-15% reduced parts prices

Enhanced Data Collection and Integration

During implementation, SDI will cleanse and catalog your master data. We facilitate this by performing a comprehensive “crib crawl” – a physical inventory of all materials in your storeroom areas. The collected information is uploaded to SDI corporate, where each part is assigned a unique SKU identification number. We then normalize, enrich, and catalog the data in the system.

For any unidentified materials, SDI resources will research the part to determine the manufacturer and detailed description information. Once identified, the material is added to the catalog with a unique stocking location and put away.

Using the cloud-based MRO3i solution ensures everyone from the plant manager to shop floor personnel have the right parts and quantity, at the right time and the right price to improve equipment availability. MRO3i comes equipped with a robust suite of tools and capabilities including auto data cleansing and enrichment, auto-deduplication, access to a master database of over 1 million validated MRO items, data dictionary of over 6,000 noun/modifier templates, asset hierarchy tools, and so much more.

This full storeroom inventory crawl enables us to build a complete master dataset of your materials catalog and locations, ensuring data integrity from the start.

ZEUS Purpose-Built Data Warehouse to Complement Data Cleansing

Since data stored across multiple systems is often difficult to consolidate, we cleanse and standardize your MRO data.

We then have two options:

- We can create a data warehouse to store the cleansed data for your reporting and analysis needs

- We can provide the cleansed data in a format for you to upload into your own system

If you choose to use our master data management software, it will become your custom product catalog. Our proprietary ZEUS system integrates data across inventories into a single platform, allowing us to track and optimize your supply program performance.

Spend Management through Automation and Catalog Management

This service focuses on improving the efficiency of handling high-volume, low-value transactions by employing effective spend management strategies enhanced by automation and catalog management. The process involves the utilization of clean, standardized data and includes consistent maintenance, such as updating product descriptions and adding new parts, to maintain information integrity. Learn more about our Catalog Management solutions.

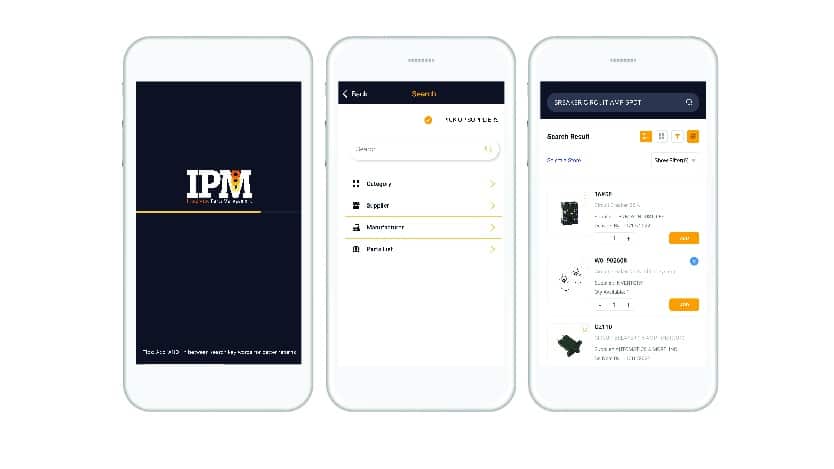

Master Data Management for Efficient Mobile Maintenance

Your mobile maintenance technicians don’t have time to search through multiple online catalogs or wait for transactions to flow through outdated technology. Techs need the speed and reliability to search based on what’s right in front of them. That’s why ZEUS’s user-friendly mobile app includes:

- Accurate pictures, updated regularly by our master data management specialists

- APIs and robotic process automation

- Attributes and detailed descriptions to improve confidence in purchasing

- Fast answers from knowledgeable service personnel

- Parts information to assist in decision-making

- Real-time inventory visibility and accuracy

- Frictionless direct purchasing with third-party suppliers

- Supplier-assisted purchasing

MRO Data Management for Extraordinary Results

Discover the powerful impact of SDI’s Master Data Management solutions on your supply chain. Tailored for procurement, maintenance, and facilities management, our cutting-edge strategies drive operational efficiency and strategic decision-making.

Contact us to unlock the utmost potential and excellence in your supply chain operations.