Home » Supply Chain Services » MRO Supply Chain As-a-Service » MRO Change Management & Continuous Improvement

Based on Project Management Institute foundations, project management fundamentals, and Six Sigma methodologies, SDI’s technical projects provide industry-specific engineers to evaluate your current inventory versus your day-to-day needs, research the market and make informed recommendations for parts and products that will reduce inventory excess and provide value-added benefits.

SDI helps our clients implement and align processes to leverage the forces of the ever-evolving market, meet business objectives, and ensure the success of their programs — a road map to achieve your desired results. Our Certified Project Management Professionals utilize a proven Project Management methodology combined with Lean and Six Sigma philosophy and practices that have brought about dramatic change – with dramatic results – for organizations of all types and sizes for over 50 years.

To increase your speed to results, and improve your rate of success, we offer a phased approach to implementing our MRO Digital Supply Chain Solutions

This phase typically takes 2-6 weeks or until the contract is signed. It’s the pre-work and planning to identify what is missing from the current process. Time spent on these efforts accelerate implementation and ensure value delivery.

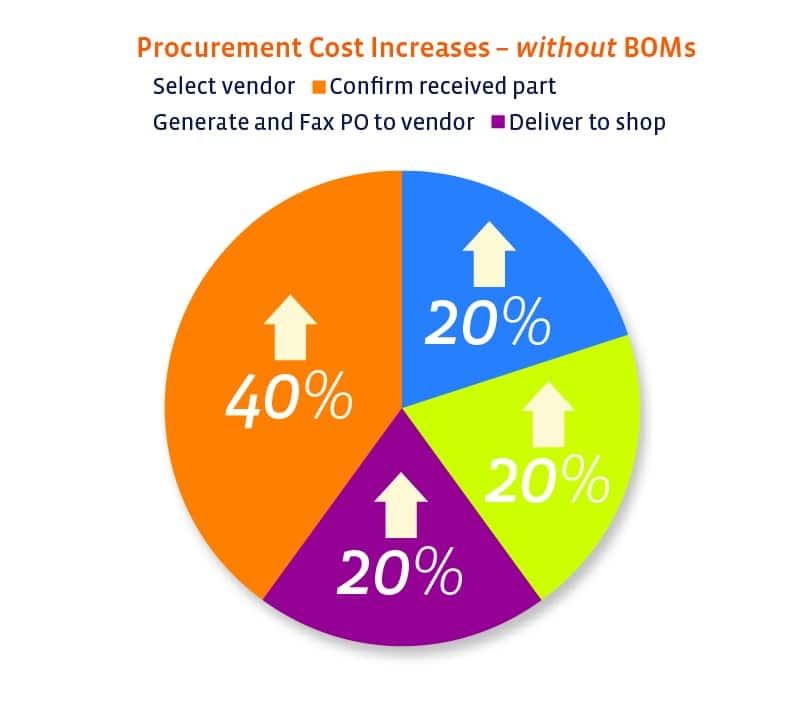

This phase typically takes 6-8 weeks and involves the pre-work that enables focused tasks. Running four parallel paths — on-site, customer set up, IT integration, and sourcing — reduces on-site resources by 75%, and the amount of change your team digests at once. This ensures a simplified and repeatable IT integration. And with the sourcing and catalog-build focused on what you actually buy, predictable piece price savings can be delivered on Day 1.

After operating in Ready Launch for the first 6 months, SDI overlays our Hypercare customer service to finalize the full integration, including systems integrations.

Because success does not hinge on Technology alone, the benefits of SDI’s Phased Implementation approach are immediate and widespread. They come in the form of reductions in implementation costs, reduced on-site resources using a less intrusive process, reduced anxiety of end users, minimal process changes, significant reductions in risk, and acceleration of value, delivering 10% or more in piece price savings.

We understand that manufacturing and other asset-intensive environments become entrenched in the day-to-day and can’t make the turn from reactive to proactive. Making the turn is not easy. You need to back out of the day to day to do this. That’s why we’re here.

SDI’s offers a number of reliability engineering solutions as-a-service or as discreet projects.

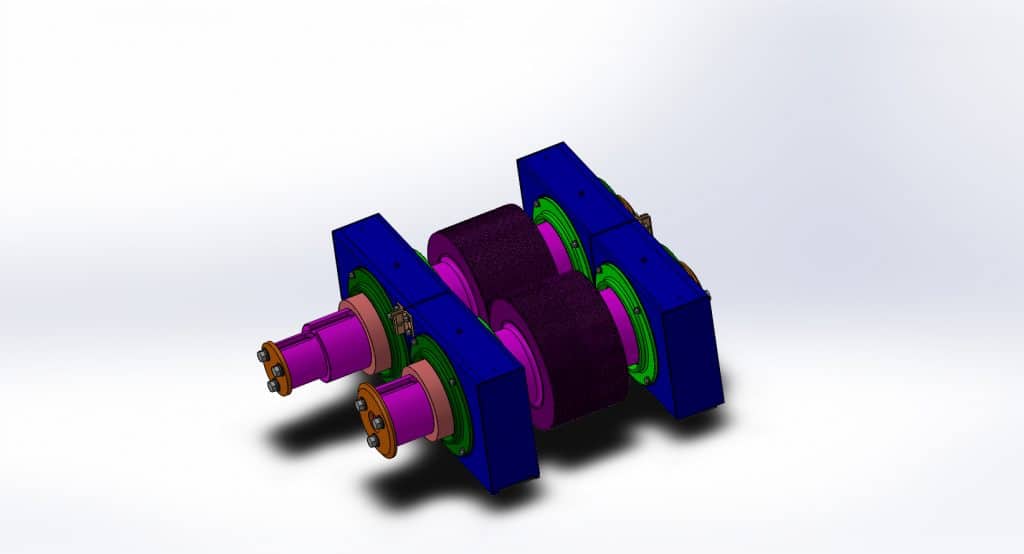

SDI can perform Reverse Engineering as a project service, giving you control over the longevity of your equipment. Often in the reverse engineering process, SDI suggests methods to manufacture the part in a way that’s stronger, or more cost effective, or fits the service better – or ALL the above. Resourcing or ‘right sourcing’ standard MRO products identified by manufacturers as OEM parts provides savings up to 50%. Benefits of reverse engineering projects include improved uptime, eliminating capital spending, reducing cost, reducing lead-times, and greater control over the longevity of your assets.

Copyright ©2024 SDI, Inc.