Companies often shuffle their maintenance, repair, and operations process into the most convenient and least time-consuming silo. They may know intuitively that it is not the most efficient way to procure and manage thousands of SKUs – many of them critical to their operations – but with all the other strategic and tactical decisions to be made, if MRO is out of sight, it’s out of mind.

But non-management or mismanagement will not remain out of sight for long. Stockouts of crucial spare machine parts, inventory that slides into obsolescence before it can be used, and exorbitant carrying costs sooner or later will thrust MRO onto center stage.

Creating Assets

MRO bears directly on company performance and profit, rather than just occupying an expense category necessary to keep production lines humming and distribution channels operating. Just as the direct supply chain succeeds only when it creates satisfied customers, the indirect, or MRO supply chain is successful only when it creates assets that are available, locatable, usable, and cost-controllable. In this context, the MRO value chain is a manufacturer’s internal go-to-market strategy, and assets are its internal customers.

MRO visibility and efficiency can ensure all of a company’s MRO processes – machinery, equipment, factories, transportation and distribution networks, vendors, service providers, etc. – all work together to satisfy their assets’ needs including:

- Reducing overall inventory and its associated costs

- Increasing fill rates

- Saving time through automated ordering

- Virtually eliminating unplanned and emergency maintenance

Account Management

Smart businesses know that some customers are more valuable than others and manage these accounts accordingly. Assets are no different. Low-cost, easily obtained, quickly used and commodity supplies can be purchased locally, sporadically, and in large quantities. Expensive, scarce, and critical materials, however, require forethought, executive involvement, and strategic planning to ensure they are available when needed. Other MRO supplies fit into a variety of other categories depending on their importance to production, quality, distribution, customer serviced, etc. and how difficult they are to procure based on the market’s complexity. The key is to invest in an account management process to analyze each SKU and develop integrated monitoring, ordering, delivery, holding, tracking, and fulfillment practices for each category. Some may be better suited to standing orders, others to trigger points, and still others to vendor-managed inventory.

Customer Satisfaction

Satisfied customers are repeat customers, and when MRO management satisfies the demands of the company’s assets, those assets will continue to contribute revenues. By engaging a qualified MRO supply chain management partner, companies transform spend into an investment in customer service in several ways:

- By understanding and predicting demand, they have the right amount of each supply on hand, minimizing carrying costs, obsolescence, and production downtime.

- By continuously streamlining ordering, receiving and order processing and to eliminate costly mistakes, duplicative parts descriptions, and misplaced or mislabeled supplies.

- By using the data and transparency their MRO logistics professional provides to identify the best stocking strategies and locations for their operation. This creates centralized ordering, lineside supply, shared facilities, just-in-time delivery or fully vendor-managed solutions.

No different from the product supply chain, the key to MRO supply is satisfying the customer while keeping costs at a minimum. When factory assets are the customer, MRO management should be geared toward service, availability, quality, and reliability that keeps them coming back for more.

SDI offers MRO service integration packages that are sure to fit your business. Fully customized and scalable, our MRO-as-a-service plans put you in control of your entire supply chain. To discover how SDI can help, call 844-235-9657.

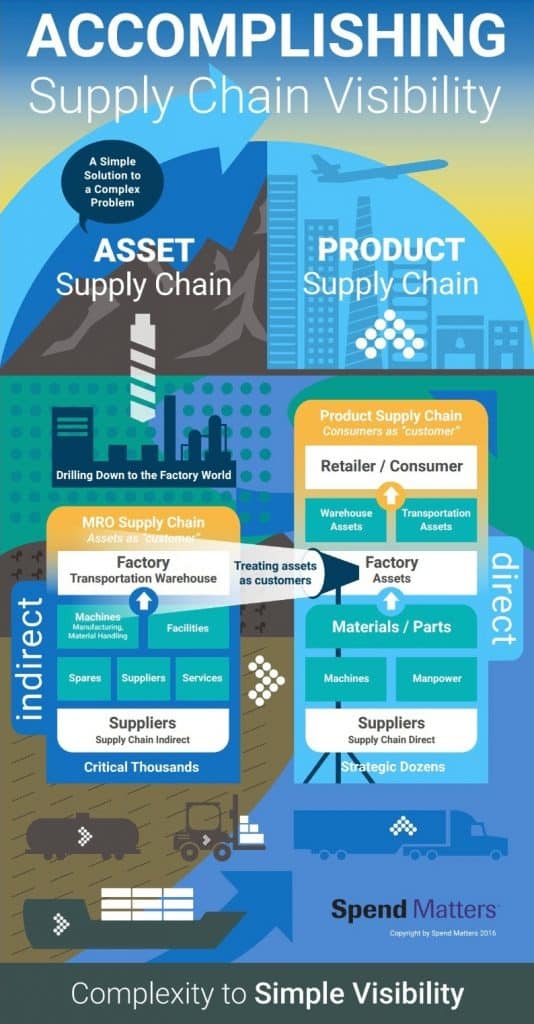

The following infographic was created by industry leader, Spend Matters and helps showcase the differences between the product supply chain and asset supply chain while also proving the commonality and overlap between the two.