Summary

More and more business leaders in procurement and maintenance are making the connection between quality MRO processes and production reliability. At SDI, we live and breathe MRO, but the cold hard reality is that MRO isn’t viewed as important when compared to direct spend. As a result, many companies do not place great value on MRO technology and instead redirect their limited IT resources to “higher value” business initiatives.

In this first part of a three-part series, we set the stage on how integrating ZEUS into their systems helped Ascend Performance Materials:

- exceed their performance goals to achieve an astounding $10million in savings per year

- reduced their processing errors

- condensed the timeframe in which invoices are paid

- improved master data management

—

The Maintenance, Repair and Operations (MRO) business process – the demand and supply chain of parts, materials, equipment and consumables necessary to keep plants and facilities operating safely and productively – is historically underfunded and typically mismanaged. Far too many companies believe that MRO is a necessary evil and a cost of doing business. The good news is that perceptions are beginning to change. More and more business leaders in procurement and maintenance are making the connection between quality MRO processes and production reliability. At SDI, we live and breathe MRO, but the cold hard reality is that MRO isn’t viewed as important when compared to direct spend. As a result, many companies do not place great value on MRO technology and instead redirect their limited IT resources to “higher value” business initiatives.

As we, and other industry leaders, work hard to change MRO perceptions and practices – we also have to be practical and deal with current realities. The reality is that manufacturers’ IT organizations are under-staffed and over-worked. They have more potential initiatives on their project list than they can realistically complete. If and when we change procurement and maintenance leaders’ perception of MRO, we still face the daunting obstacle of motivating the IT organization into action.

Our response to overcoming this daunting obstacle is to deliver a compelling, can’t-miss promise to seamlessly integrate disparate systems, provide reliable and transparent end-to-end data, reduce manual interventions and workarounds, and facilitate better resource conversations between procurement, maintenance, planning and production. In addition, we condense the timeframe of SAP integrations from an average of 9 months to 1 month – with minimal involvement of the client’s already stressed and stretched IT organization. A can’t miss value proposition…right?

Not exactly. Here’s the new perception gap that we need to work on closing. IT organizations have heard these promises before and have become conditioned not to believe the claims of fast, low-cost, integrations with little IT involvement. The engrained IT perception, especially when it comes to SAP integrations, is that the process will be slow, difficult and expensive due to custom coding – that it will require a great deal of support from corporate IT. Most IT leaders are very suspicious of integrator claims. This leads to delayed decisions or no decision, and since MRO is viewed as cost of doing business, the promise of a fully integrated MRO process to support the reliability goals of the organization gets buried deep on the list of IT priorities.

We have to change the context of MRO to change perceptions of MRO. MRO isn’t just about piece price or the cost of parts. MRO is a key element of production reliability and uptime management. Through our 45 years of client work, market intelligence and industry benchmark studies, we have found that maintenance represents from 15 to 40% of the total product cost (source Vesta Partners) and 40-60% of overall maintenance cost is MRO related (SDI).

Supporting Insights from (IHS Research and Aberdeen Research)

- 4.7% unscheduled asset downtime for best-in-class vs. 16.2% for laggards

- 11% decrease year-over-year maintenance cost for best-in-class vs. 5% increase for laggards

- 50% of work order cannot be completed because of technicians are waiting on parts

- 55% of MRO inventory has not moved in 3 years and 30% of MRO inventory will never be used

- 62% of stock order points are wrong

- 87% of order quantities are not accurate

- 97% of lead times are incorrect

- 86% of storeroom attendants have had no formal training in inventory management

They don’t call them Game Changers because processes are widely accepted and outcome expectations are low. Game Changers always begin with a good amount of skepticism, a great amount of pain, and an overwhelming drive to make things better.

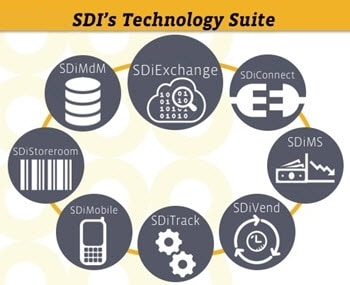

Learn, with a real-life example, how a company’s decision to overcome its skepticism and place higher value on MRO technology drove valuable organizational benefits in part two of our series, “Case Example of Skepticism, Pain, and Drive to Improve.” To learn more about the technology platform that enables SDI’s indirect supply chain management, click here.