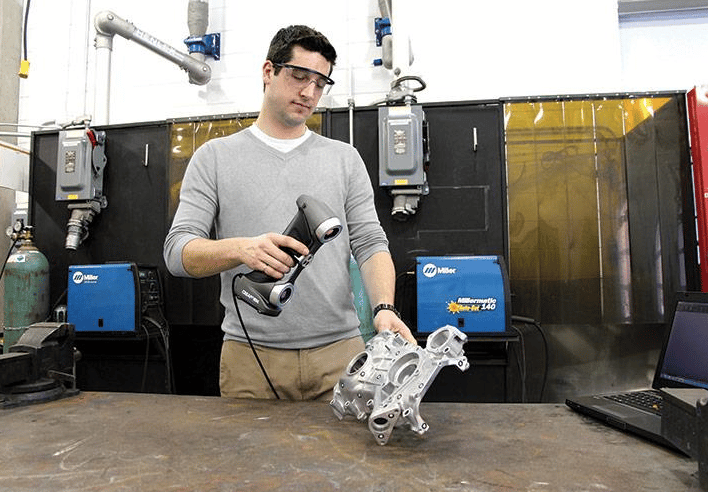

The high cost of original equipment manufacturer (OEM) replacement parts for production equipment has always been a challenge for SDI customers. The OEMs are often the sole source of supply for the spare parts and as such, have no motivation to negotiate better pricing, forcing customers to pay very high prices for equipment spares. To help resolve this, SDI has purchased a new tool to help our customers with OEM spare parts sourcing and pricing. The Creaform Handy Scan 700 3D laser scanner (with accompanying software), gives the SDI Engineering Services Team the tools to reduce those OEM costs, reduce lead times and in some cases, even improve the life of these parts. Here’s how.

3D Laser Scanning and How it Works

On-site SDI Reliability Engineers (R.E.’s) will work with our customers to identify candidates for conversion from OEM to MRO commercially available parts. Once part candidates have been selected, SDI will utilize the 3D scanning tool, which guaranties accuracy of up to 30 microns (.001”). The scanning software allows the scanned part to be converted into Solid Works software where our R.E.’s can assess and actually improve on the part design.

This technology enables our R.E.’s to decrease the OEM costs by as much as 70%. Maintenance events will be decreased by designing out failures and designing parts with higher inherent reliability. When scanned and re-engineered parts are sourced locally:

- Lead times are improved

- Inventory can be reduced

- Just in time” opportunities are created

The scanner allows SDI to build a network of shared part solutions across its customers, eliminating the need to partner with outside vendors for re-engineering needs.

Pairing 3D scanning technology with Solid Works 3D modeling software gives SDI a unique advantage over other vendors that are currently providing similar services. Other outside vendors typically own the drawings produced making it virtually impossible for our customers to have the option to competitively bid the parts. With SDI, scanned part drawings can be shared with the customers, enabling our organizations to jointly benefit from the technology. In addition, outside vendors utilize their own manufacturing network, again holding the customer captive to the vendor’s distribution network, while SDI partners with local manufactures to reduce lead times and keep costs in check. While outside vendors typically are not experts at failure analysis and design improvement, focusing only on parts duplication, SDI can provide exact duplication along with design improvement with 3D scanning.

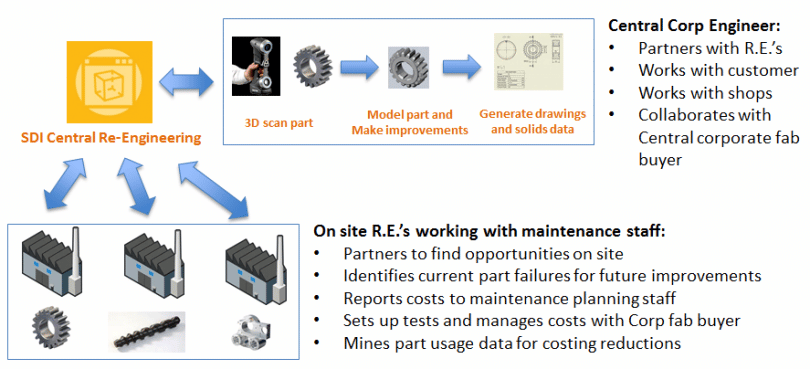

The engineering services team is made up of engineers from all facets of the discipline. This gives SDI strength and knowledge to cover different challenges across our customer network. With that being said, a new Corporate Engineering position is being developed (located in Bristol, PA) to compliment the 3D scanning technology and provide needed design support for the site R.E’s.

The intent is to take the detailed work needed from the R.E.’s and place it in the hands of a specialized design engineer. This will allow the site R.E.’s the time to research the opportunities and focus on the improvements, and the best possible part test scenarios with the customer. The Corporate Engineer will focus on the parts accuracy, any design changes required, 3D scanning procedures, 3D modeling, producing the engineering drawings, and getting the parts machined.

While the corporate engineering position is being developed, the 3D scanner will reside at the MillerCoors Golden site for pilot program development and OEM part scanning. During this period, the new scanning tool will be available to any other R.E.’s that may have conversion opportunities. This tool will give the Engineering Services group an edge over other suppliers providing this type of service and generate real value and immediate cost savings to our customers.

Additional advantages of the 3D laser scanning tool from SDI:

- Maintenance: Document as built modifications to assets, accurately measure wear and tear on critical components and tooling. Check de-formation and geometry analysis. Perform interference analysis of parts.

- Design (Re-engineering): 3D scan-to-CAD. Scanning old parts that are no longer manufactured anymore (Restoration), and rapid proto-typing of solutions that will increase up time and reduce failures.

- Manufacturing: Reverse engineering of dies, molds, fixtures, jigs and patterns for future use. First article inspection on parts. Part to CAD inspections.

Once the 3D scanning technology has been established within the Engineering Services team, other possibilities will be explored. The uses and possibilities are endless for this exciting new tool. This is another example of how SDI continues to be innovative and thought leaders in the MRO industry.