The COVID-19 pandemic proved that global and regional surges in demand can critically impact supply chain in education sector, exposing the faults of conventional wisdom regarding supply chain: that it’s most efficient and effective to have a single supplier or source for materials.

Personal Protective Equipment and PPE procurement for schools is essential to stopping the spread of the COVID-19 virus. When demand for PPE is high, it’s best to have access to a large and diverse pool of suppliers and manufacturers. This diversification exposes schools’ vulnerability to supply shortages and limits their capabilities in managing supply chain disruptions.

Why did this happen?

With the pandemic impacting virtually every region, the supply and demand shock has had much greater impact. And because the COVID-19 is a novel virus, previously unidentified in humans, this led to much uncertainty. This, in turn impacted supply chain in the education sector.

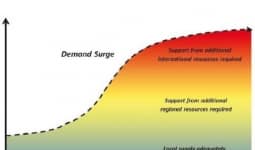

The PPE supply chain was built for efficiency, which means there was little to no excess inventory – no “slack in the system.” When the pandemic hit, many school and business leaders reacted with a panicked type of approach, ordering as many supplies as they could. This put immediate stress on the supply chain. The heavy dependency on offshore production meant there weren’t inventories of PPE readily available for schools and other institutions.

Have we experienced something like this before?

The short answer, no.

While there have certainly been outbreaks in recent history, such as the 2003 SARS coronavirus, they had a much smaller impact, and didn’t impact the global market as extensively as COVID-19.

Something else that’s unique about this pandemic are the federal mandates that were put in place to redirect PPE to hospitals, first responders and other critical healthcare providers, which led to additional chaos and supply chain disruptions.

What’s the current status of the PPE supply chain?

The PPE supply chain has become more stable, but that’s due to diminishing demand, versus an increased number of supplies. We’re not currently experiencing supply shocks, but we are experiencing volatility. Domestic suppliers have ramped up production, but nowhere near what’s needed to build a resilient, long-term supply chain.

In an attempt to better coordinate the production and distribution of masks, the Federal Emergency Management Agency (FEMA) is collaborating with manufacturers, distributors, buyers and government officials – made possible under a provision of the Defense Production Act that allows the federal government to consult with businesses for emergency preparedness and response.

Another important consideration that may impact supply and demand: PPE is perishable. Products such as face masks, hand sanitizer and nitrile gloves all have an expiration date, which means stockpiled items stockpiled in March 2020 could soon become an expensive burden. This issue has made clear that school district leaders should carefully plan for “the final mile” of distribution that’s required to get supplies from storage to school buildings.

PPE Procurement for Schools

The unprecedented nature of the COVID-19 pandemic exposed gaps in the PPE supply chain and the ability to manage supply chain disruptions. Supply chain in the education sector is no exception. But the pandemic also provided opportunities to strengthen it.

Many K-12 school districts have outdated models for supply chain management and procurement, and lack the technology platforms and processes that other industries have put into place. There’s an opportunity for district leaders to learn from what we’ve experienced in managing supply chain disruptions and modernizing PPE procurement for schools.

Relying on just-in-time inventory is risky, but stockpiling unneeded supplies is equally dangerous. We recommend performing a PPE risk assessment to mitigate against future shocks, and securing access to a strategic reserve that can be accessed immediately when a surge requires it. Contact SDI today to discuss your needs.