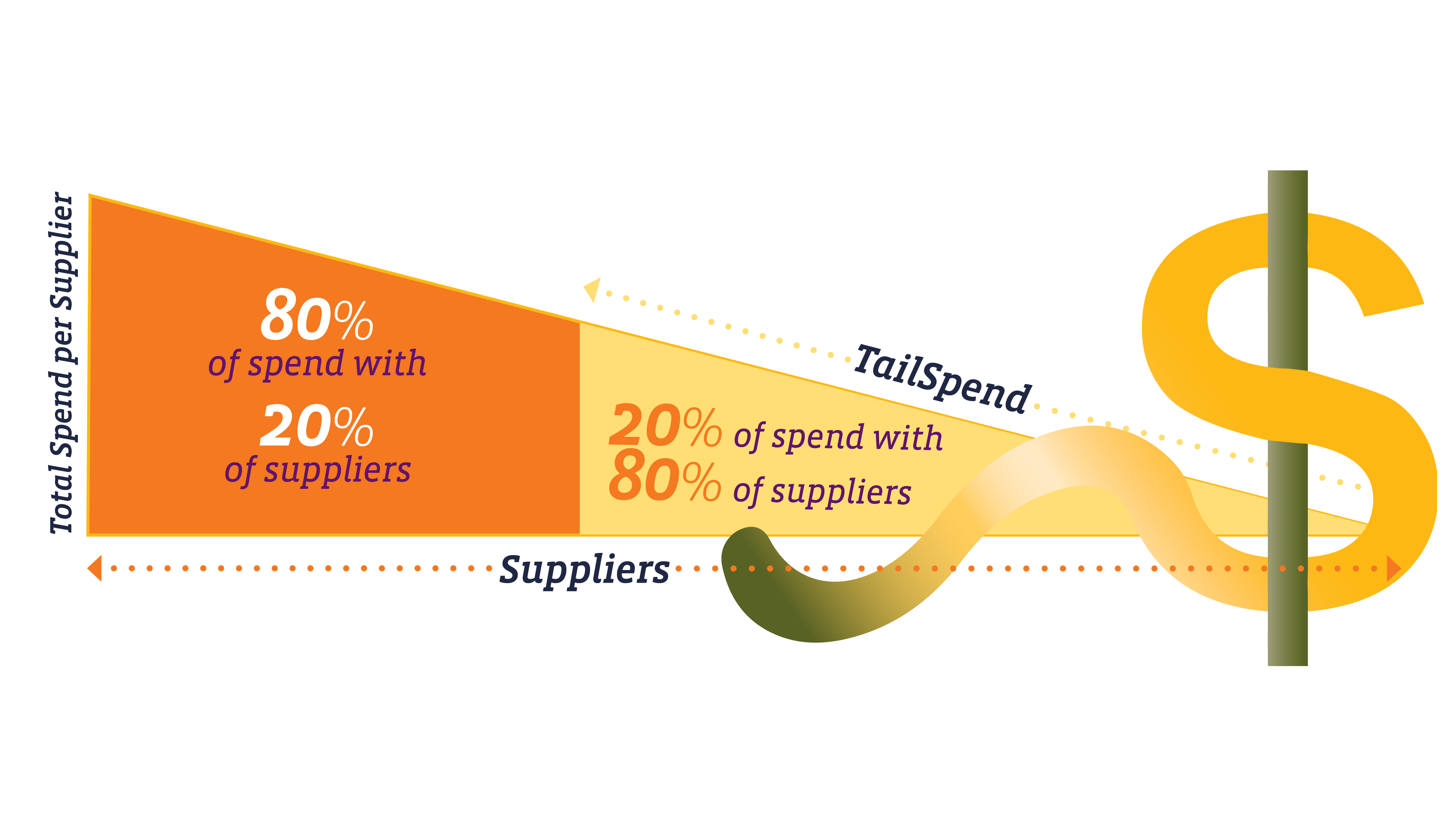

Maintenance, Repair, and Operations tail spend may seem insignificant, given that it only accounts for 20% or so of a manufacturing business’s MRO budget.

But because organizations require are so many of these routine, low-value, high-quantity materials in their operations – everything from disposable rubber gloves to machine cutting blades, to lubricants and cleaning materials – they can quickly spiral out of control. That last 20% expenditure can easily encompass 80% or more of a company’s SKUs and a similar proportion of suppliers.

This fragmentation creates supply management and operational challenge that until several years ago many companies considered more trouble than it was worth. Businesses were unwilling to devote the resources required to track, control, and optimize the sheer volume of transactions, sporadic demand, and lack of visibility into their tail spend management practices.

But today’s managers have undergone an attitude adjustment. Increasingly, manufacturing businesses have come to realize that active, aggressive MRO tail spend management can cut up to 10% from their operating costs – cash that flows directly to the bottom line. In a world of shrinking profit margins, cutthroat competition, and stringent customer demands, tail spend analysis presents an environment too target-rich to ignore.

The Devil’s in Detail Spend

While the newfound appreciation for tail spend’s impact on company profitability is refreshing, actually bringing spending and vendor relations for so many items under control remains an exercise in herding cats.

Unless you develop and implement SDI’s tail spend information management, collaboration, and automation game plan:

- Active Management: Given their low value and “insignificance,” tail spend items routinely evade active oversight. They may be purchased outside established procurement channels. This maverick spending not only incurs higher costs compared to on-contract transactions but also disrupts accurate inventory tracking. By centralizing a greater percentage of tail spend, organizations simplify acquisition processes and consolidate suppliers to unlock volume discounts and reduce overall procurement costs. Trusting this task to SDI’s SaaS inventory management team gives you real-time inventory visibility. We track all purchases optimize stock levels, and eliminate the costs associated with carrying excess inventory. We perform advanced analytics and reporting so you can take advantage of usage and spending patterns to identify opportunities and make better decisions.

- Automated Purchasing: By leveraging technology to automate the resupply of these routine items, companies can reduce manual intervention, minimize errors, and accelerate procurement cycles. This automation ensures that repetitive tasks are performed swiftly, freeing up procurement teams to focus on strategic activities. Automation should be extended to electronic confirmation of purchase orders, shipping details, and invoices. Investing in software that enables real-time tracking and SKU audits ensure accuracy and minimize lead time between reorder triggers and replenishment. reducing delays and improving accuracy. Partnering with a third-party expert to mobilize specialized knowledge, technology, and industry contacts to streamline procurement processes cuts down administrative costs and enhances transparency and compliance. For instance, SDI optimizes our clients’ supplier selection, negotiates favorable terms, and manages contracts. Our expertise helps achieve additional savings through economies of scale.

- Robust Data: MRO supply chain data is often complex and voluminous, creating environments prone to waste, duplication, and missed opportunities for cost savings. Streamlining data by making part identifications consistent, eliminating obsolete SKUs, and creating consistent parts taxonomies across the enterprise, organizations gain clarity on their spending patterns, optimize inventory levels, and make more informed procurement decisions. Sophisticated data analytics tools process vast amounts of procurement data, providing insights into spending patterns, supplier performance, and potential areas for consolidation. Analytics can identify opportunities for bulk purchasing, accurately predict future maintenance needs, and highlight tactics for negotiating more favorable contracts with suppliers. SDI has developed processes and tools to help clients cleanse and align data, analyze it in real time, and mobilize it to reduce the number of SKUs and find the most reliable and economical suppliers.

Though often overlooked or deemed too resource-intensive, tail spend management can deliver transformative results.

Tail Spend in a Tailspin?

If your tail spend is spiraling out of control, collaborating with SDI puts industry expertise, cutting-edge technology, and dedicated resources at your disposal.

SDI’s transaction processing, process visibility, spend analysis, and other tail spend management services unlock the full potential of your procurement processes. With our experience and innovative technology, we can help you achieve greater control over your tail spend, which contributes to important cost savings and overall operational excellence. Contact our experts today to learn more about SDI’s tail spend management solutions and supply chain-as-a-service offerings.