Supply Chain Services

Home » Supply Chain Services

About Supply Chain Services

SDI is an industry pioneer in supply chain solutions and services, renowned for over 50 years of experience in guiding facilities and plant maintenance leaders towards operational excellence. As specialists in integrated parts management, SDI has transformed procurement services and warehouse management solutions across a spectrum of industries by collaborating as an extension of your supply chain to augment, enhance, and accelerate your strategy.

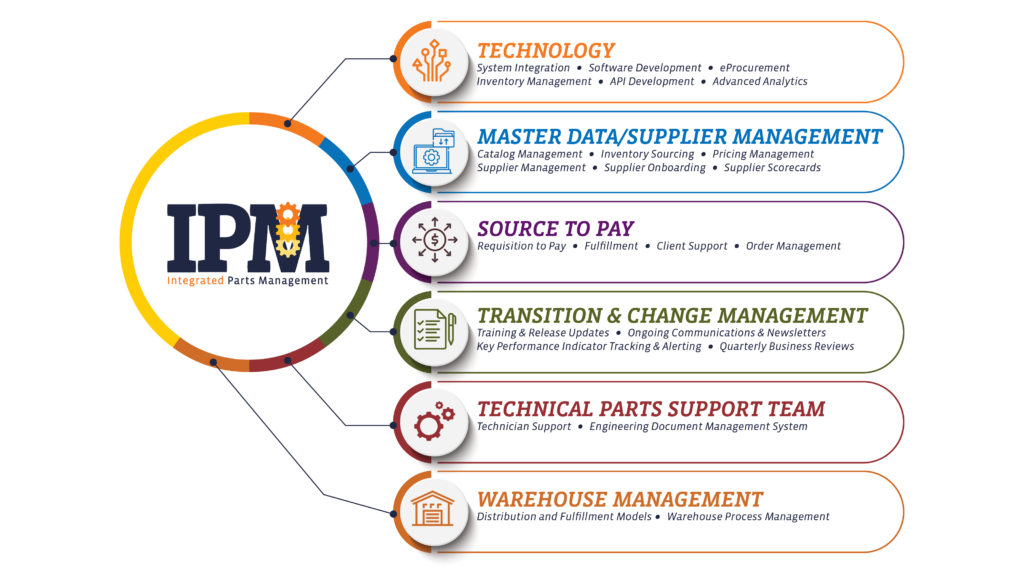

What is Integrated Parts Management?

IPM is an end-to-end, parts management program that aligns and integrates with your plant maintenance and facilities management (FM) strategy, enabling you to address and optimize the 20-30% of your annual budget that is often neglected.

The connected digital supply chain approach to parts management:

- Improves end-to-end data transparency and workflow visibility for improved control and predictability in demand

- Improves maintenance productivity and wrench time by as much as 20%

- Decreases total cost of ownership of the supply chain of parts and materials critical to maintaining revenue-generating assets, facilities, and plants by more than 10%

Both in-sourced and third-party technicians can leverage the digital supply chain to locate and purchase parts and materials for both preventive and reactive maintenance.

Purpose-Built for YOUR Supply Chain

After developing an understanding of each client’s specific objectives and how they’re measured, we structure specific benchmarking to optimize how supply chain fits into their workflows related to parts, labor and asset management – then we design and implement digital supply chain solutions to address areas of improvement and optimization that directly impact the client’s KPIs.

- Tech/mechanic productivity & efficiency

- Reduced parts costs and consumption

- Working capital management

- Back office simplification and cost reduction

- Enterprise visibility and control

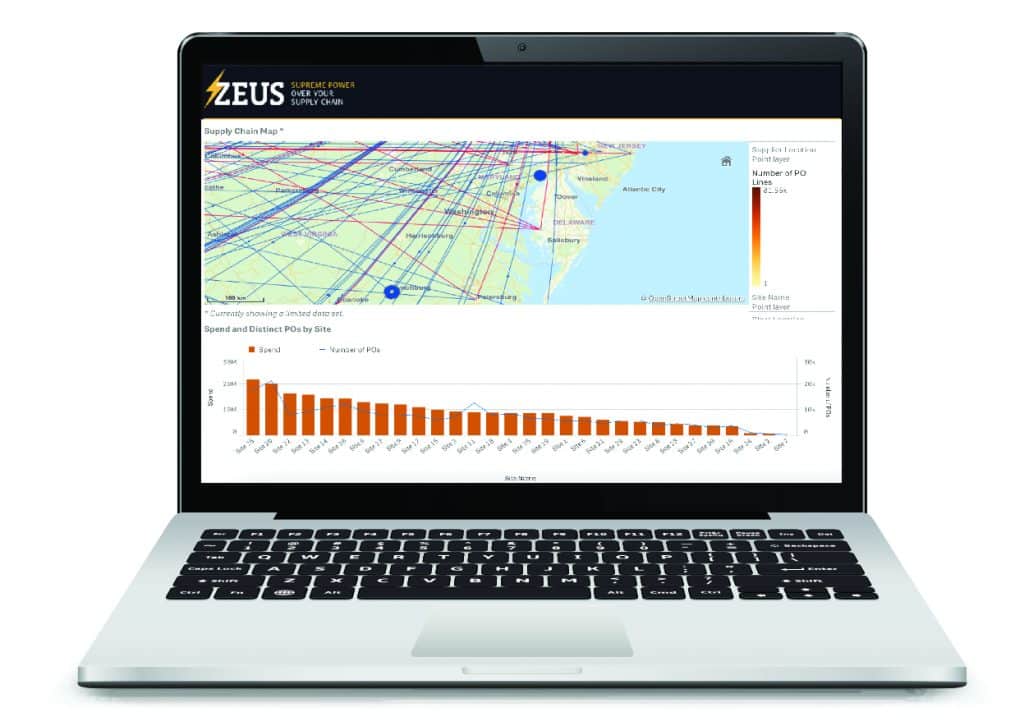

The Future of Digital Supply Chain is Now

Our Purpose-Built Supply Chain Solutions

Cooperative Purchasing

By leveraging the collective buying power of the group, members can negotiate better pricing and discounts from suppliers, streamline their procurement processes, and improve the overall efficiency and resiliency of their supply chain.

MRO Supply Chain As-a-Service

A full life-cycle, enterprise maintenance, repair and operations supply chain program powered by a purpose-built supply chain infrastructure of people, process, and technology…as a Service

Master Data Management

Transform your supply chain with SDI’s FM and MRO Master Data Management (MDM) solutions. Explore our strategic approach to data integrity, operational uptime, and decision-making across procurement, maintenance, and facilities management.

Supplier Management

SDI’s Supplier Relationship Management (SRM) team specializes in optimizing your supply base’s capabilities and assets in alignment with your business strategy. We manage the entire lifecycle of supplier relationships, from vetting and onboarding to negotiations and performance management, ensuring that all FM, MRO and indirect spending enhances your overall savings and program value.

Source to Pay

SDI specializes in data-driven Source to Pay (S2P) services, enhancing visibility and control over Facilities Management (FM) and Maintenance, Repair, and Operations (MRO) procurement processes. Our approach maximizes addressable spend, drives contract compliance, and implements strategic improvements, reducing administrative burdens and invoice processing costs in FM and MRO operations

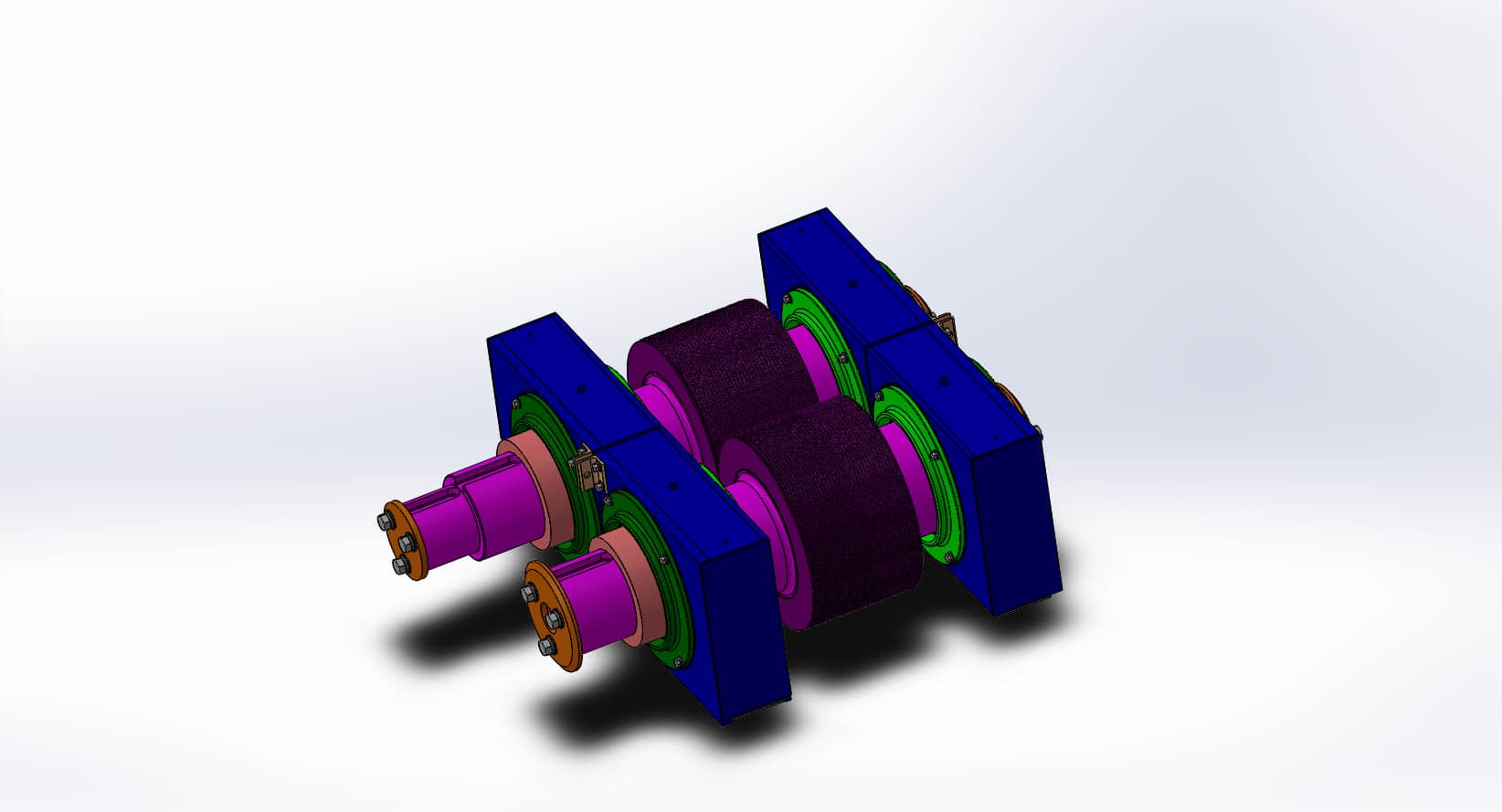

Critical Spare Parts Management

SDI’s solution prioritizes operational continuity by minimizing downtime and optimizing maintenance costs through strategic management of critical spare parts. We identify essential assets, forecast annual demand, and analyze safety stock requirements, tailoring our approach to meet your organization’s specific performance objectives.

Storeroom and Warehouse Management Services

Experience enhanced supply chain efficiency with SDI’s Storeroom and Warehouse Management Services. Through intelligent technology and specialized expertise, we optimize inventory levels, reducing overall costs, and preventing obsolete inventories and stock-outs.

Reliability & Continuous Improvement

SDI supports manufacturing and asset-intensive environments in transitioning from reactive to proactive strategies, facilitating a focus on reliability and continuous improvement. Our diverse range of reliability engineering solutions are available as comprehensive services or discrete projects, tailored to meet specific operational needs.

Implementation & User Adoption

SDI excels in steering organizations through essential transitions in Facilities Management (FM) and Maintenance, Repair, and Operations (MRO) supply chain management, utilizing a harmonized approach of Project and Change Management. Our specialized strategy ensures not only the accomplishment of vital operational tasks but also fosters an environment where individuals seamlessly adapt to enhanced processes, systems, and organizational structures.