Home » Supply Chain Services » MRO Supply Chain As-a-Service » MRO Supplier Management

SDI, at its core, is a supply chain management company that is focused on creating client value through the efficient and effective management of the MRO supply chain process. The MRO supply chain is a highly complex, fragmented and evolving segment of the business that is a core enabler of business operations. It can impact both the top line and bottom line of many businesses.

As one of the leading supply chain management providers, SDI works to establish mutually beneficial relationships with our supplier network and your existing supply base. The SDI team handles all supplier negotiations, sourcing, and performance management to ensure that all MRO and indirect spending contributes to your overall savings. After a comprehensive data review, we provide strategic sourcing recommendations and source to pay solutions for a truly integrated supply chain. This includes the right sourcing, supplier segmentation, re-sourcing, product standardization, and more.

SDI maintains a brand and supplier neutral approach within our sourcing & purchasing activities in order to align with the needs of our clients across a wide spectrum of industries and with varying and distinctive needs within each of their areas of operation. Whether that be unique product manufacturing activities across a set of client locations or the need to service more than a thousand independent schools with unique requirements.

With this complexity there is a need for a varied and extensive supplier network. SDI maintains thousands of supplier relationships in order to meet the needs of our clients. This provides our clients with access to the items they need, when they need them, whether they are for newly acquired assets or assets that have been in use for multiple decades. Access to SDI’s vast supplier network simplifies our clients’ business as they are no longer required to maintain relationships with these suppliers, thereby simplifying their supply base and allowing them to focus on core competencies.

SDI leverages the fundamental concepts of SRM with a focus on a collaborative relationship that provides for improvements in quality, supplier and SDI performance with respect to delivery, ordering and efficient business practices. SDI leverages our supplier network to ensure that our clients receive the best value for the purchasing dollar. With over 50 years of competitive bidding and frequency to market, SDI is able to achieve competitive market pricing, either for longer term, repeat stock purchasing activity or for one-off non-stock transactions.

While both our clients and SDI seek to reduce costs through our purchasing activity, it is equally important items be available on-time. Therefore, while price is a key factor, a supplier’s ability to meet SDI’s client delivery schedule and meet other client objectives also influence supplier selection.

It’s a common problem: sourcing groups cut deals, but the people on the floor don’t use them. With so many people throughout the organization empowered to purchase, there are inevitably rogue purchases. At the end of the day, all you can do is measure the non-compliance and lost savings.

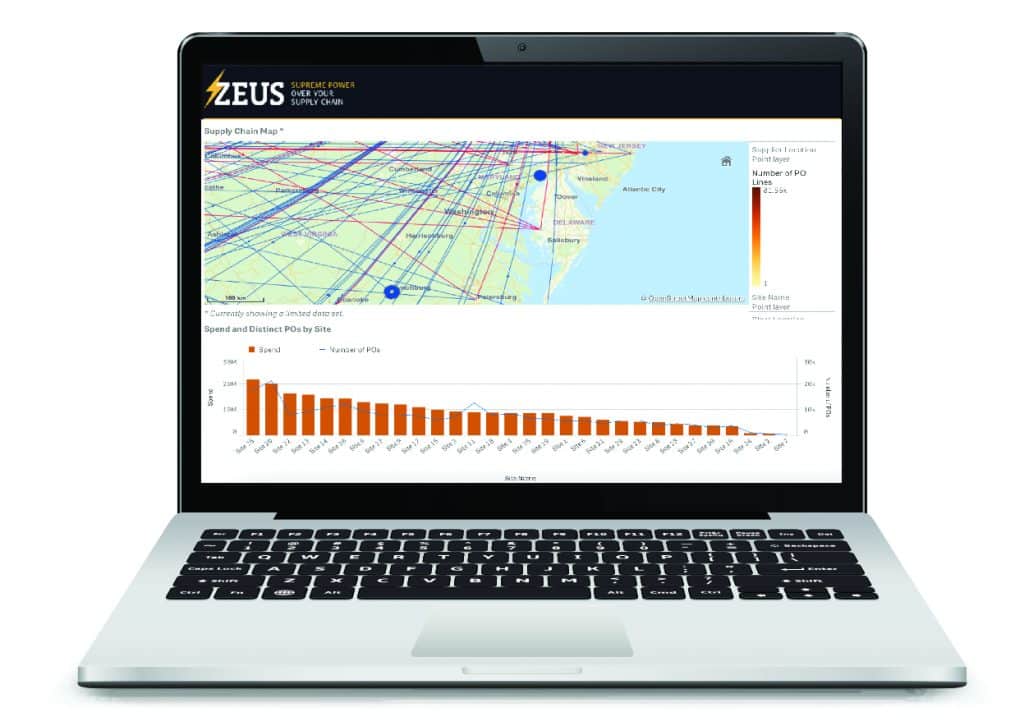

Even when contracts are honored, that doesn’t always ensure savings. You might see higher compliance percentages, but money is still lost if you’re buying the wrong product from that supplier. SDI has a proven solution that leads to true compliance. We start by ensuring that you’re buying the right part from the right supplier. Then, through our proprietary technology, we build in spending procedures, budget controls, dollar limits and approval processes that enforce those processes, leaving you in complete control.

Another important task involved in supplier relationship management is the performance of the supplier. Performance is much more than compliance. Establishing strong contract relationships and ensuring buyer and supplier compliance to those agreements is one part of delivering value. Value from a supplier partnership comes through innovative and collaborative activities that focus on solving the customer’s problems.

Supplier performance objectives and measurements are directly tied to your overall objectives. We work together with you and the supply base to realize shared goals. This is more than the intersection of common goals seen in co-operative ventures, but a deep, collective determination to reach an identical objective. Within the MRO Supply Chain collaboration can lead to improvements in supply availability or delivery. It can support improvements in overall inventory management, helping to improve customer financials. It can support the identification, review and approval of alternative parts that reduce replacement costs, improve productivity and support reductions in the total cost of ownership or improve overall equipment effectiveness.

Within a focused and collaborative supplier relationship management strategy there is significant opportunity to bring about improvements in supplier quality. In part this is an outgrowth of investment in regular meetings with the supplier that focus on all aspects of business performance. Further it can be enabled through the sharing of data related to product failures within the various client environments. This data can be effectively captured and leveraged with tools specifically designed to address the warranty, service, reparability and maintenance of MRO items.

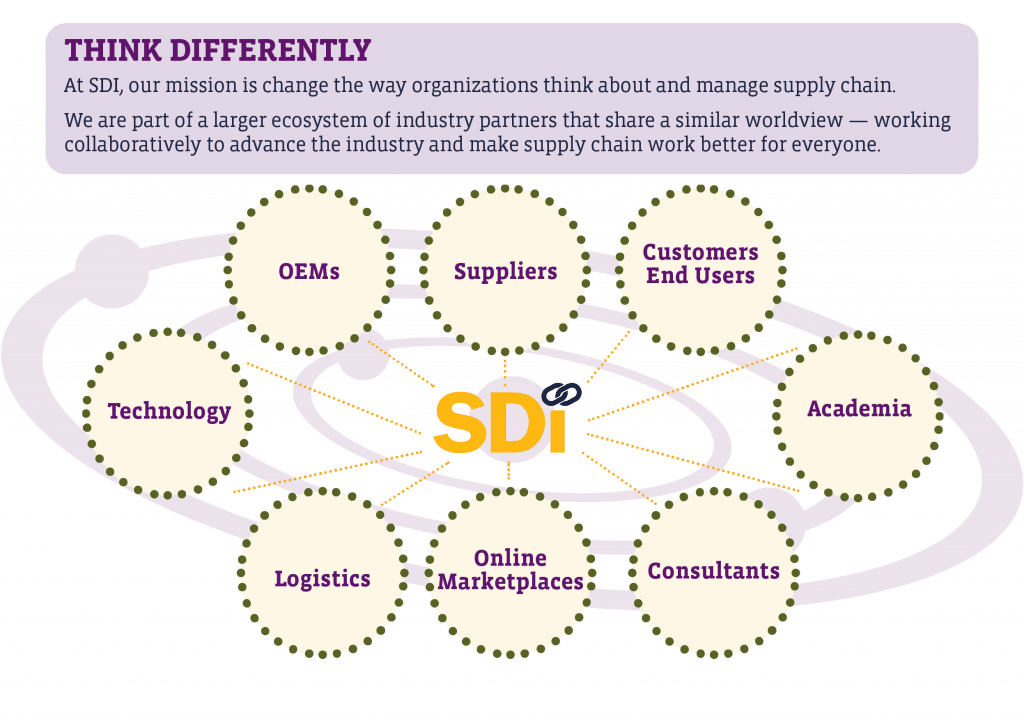

SDI’s Supplier Relationship Management program contributes to our ability to manage our supplier relationships with a degree of effectiveness and efficiency that is not generally possible within our clients’ environments given the sheer number of suppliers and interactions required to manage the MRO supply chain. SDI goes beyond traditional SRM practices to form an ecosystem within the MRO supply chain that delivers maximum value to our clients – through access to new technology, best practices in storeroom and inventory management, reliability and engineering services and cost management.

Copyright ©2025 SDI, Inc.