Home » Supply Chain Services » MRO Supply Chain As-a-Service » MRO Source to Pay

An analytics-driven S2P approach allows greater visibility into the MRO supply chain, gaining more spend under contract through category expertise, and driving compliance to negotiated contracts through a hybrid center-led and on-premise process that implements improvements to realize newly identified savings.

SDI’s source to pay service starts with our strategic sourcing strategies. We first set up a strategy for your stock items, consumables and break/fix items that are generally inventoried for regular usage. The MRO procurement process for these items is automated and continually runs against our adaptive demand planning algorithms, to constantly optimize inventory levels.

Our hybrid S2P model lets us leverage our entire portfolio for more streamlined, efficient and scalable MRO and tail-spend procurement processes. Our procurement group focuses on compliance to pre-determined sourcing strategies, while our buyers’ deep category and industry knowledge helps ensure accuracy and the most efficient outcomes. The center-led S2P indirect procurement model allows our buyers to focus on your overall MRO supply chain needs, while on-premise resources provide high-level customer touch points.

SDI follows the principles of both Lean and Six Sigma in our processes. This commitment allows us to create the maximum value through our sourcing exercises to deliver maximum improvement throughout every phase of our digital supply chain management services – all carefully designed to fit each client’s unique business objectives.

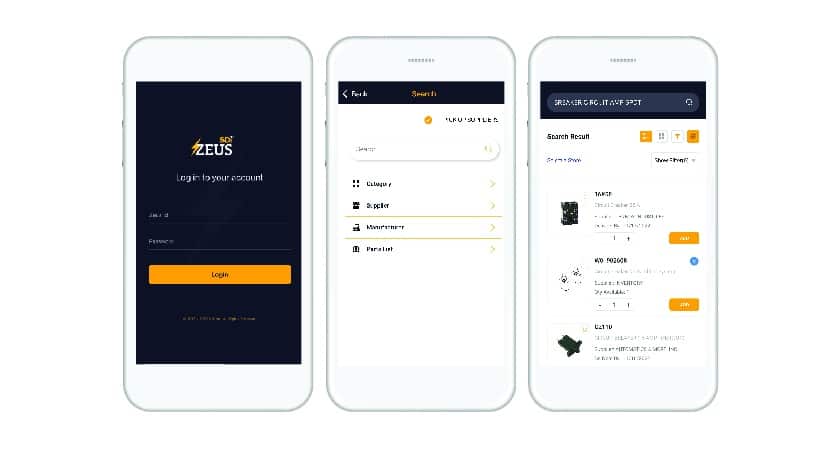

Customer support is provided in multiple layers starting with the on-site team and our Site Manager. The Site Manager can be contacted at any time. Additional customer service is provided though our Central Operations Group located in our corporate office in Bristol, PA. 24×7. Emergency support is available via an 800 number. Inbound inquiries can be sent in app, via phone, email, or fax. SDI has an incident log tool within our ZEUS system to log and track issues and incidents. Robust incident automation tools allow any user to log issues and route them to the appropriate resource for resolution. Reports on open issues, time to resolution and issue status are also available.

SDI utilizes electronic data transmissions with its supply base to streamline transactional processing—passing the savings on to our clients. By communicating orders, acknowledgements and deliveries from SDI’s suppliers, our system ensures all purchase orders are delivered automatically and all MRO purchases are updated in a single repository to be easily viewed by our clients – no need to chase POs. We confirm electronically, so client sites always know when to expect delivery.

From a billing perspective, SDI invoices its service fee and the pass-through cost of product purchased in a summary statement twice per month. This eliminates the hundreds, if not thousands, of vendor payments currently made each month – a tremendous reduction in processing costs.

SDI’s people, process, and technology have enabled the worlds’ most efficient supply chains for over 50 years. Our passion is supply chain, and we’re driven to enable organizations to achieve tremendous savings and efficiencies, improving their lives overall. Contact us today to learn more.

Copyright ©2025 SDI, Inc.