Home » Supply Chain Services » MRO Supply Chain As-a-Service » MRO Technology

The ZEUS digital supply chain management platform is purpose-built to create critical transparency between your Asset Performance Management and Supply Chain Management strategies. ZEUS can be easily integrated with your existing system as a plug-n-play platform, providing an easy-to-use and seamlessly connected process for requisitioning material and other supply transactions.

The advantages are obvious right from implementation – processes are streamlined, workflow improves, and productivity increases. Redundant practices are also eliminated, and your entire organization saves substantial time and money.

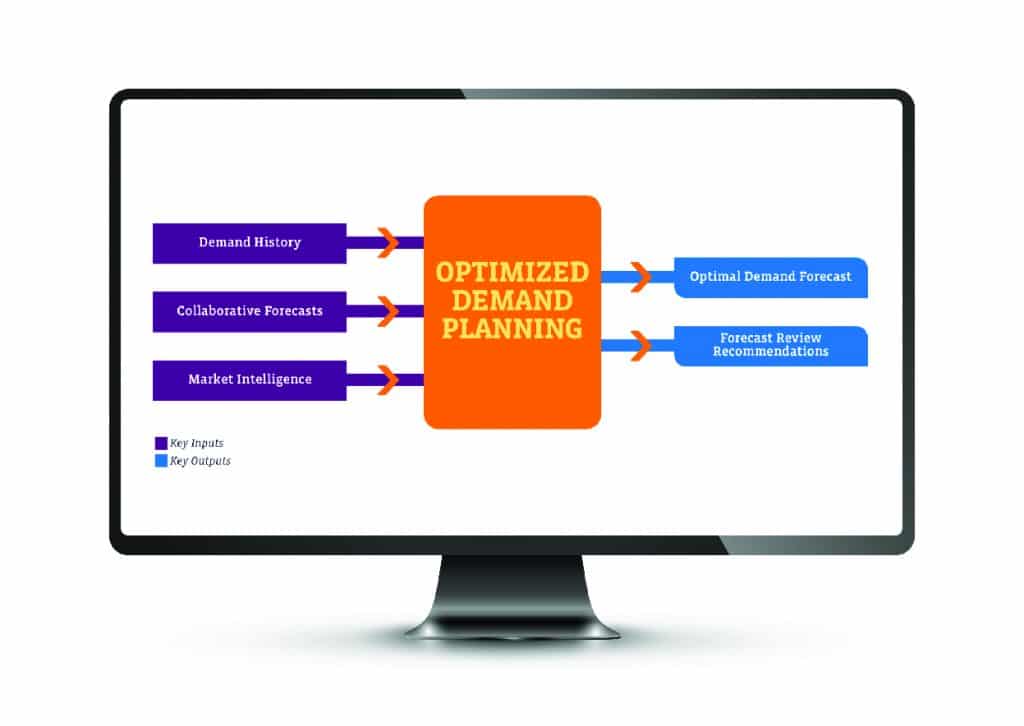

Organizations have become more data savvy as industry has adopted smart factories and IoT connected assets. In today’s digital economy, data drives real-time agility, allowing organizations to respond to supply chain disruptions as they evolve. Advanced analytics, based on continuous intelligence from multiple datasets and real-time information, establishes intelligent analytics pipelines that break down the silos inherent in MRO supply chains and allows for supply chain optimization.

A purpose-built MRO analytics tool, ZEUS, can take any manner of data and use it to help pinpoint where best to drive efficiencies in supplier consolidation, item standardization, inventory replenishment, cost reduction, and productivity improvements.

ZEUS Data Analytics helps you leverage work order, procurement and inventory data to generate meaningful insights and improve decision-making with transparency across a broad array of CMMS and ERP systems. Data literacy is essential in the shift for manufacturing and other asset-intensive industries to adopt digital technologies that enable them to thrive in today’s world. SDI’s Data Analytics provides you with a road-map to de-risk the supply chain, identifying issues, planning for continuity, preventing overspending, and pinpointing where to implement real-world changes to meet your objectives.

SDI has also developed API connections with major shippers like UPS and FedEx that allow real-time delivery updates based on tracking information, so maintenance teams can better plan their work schedules and reduce equipment downtime.

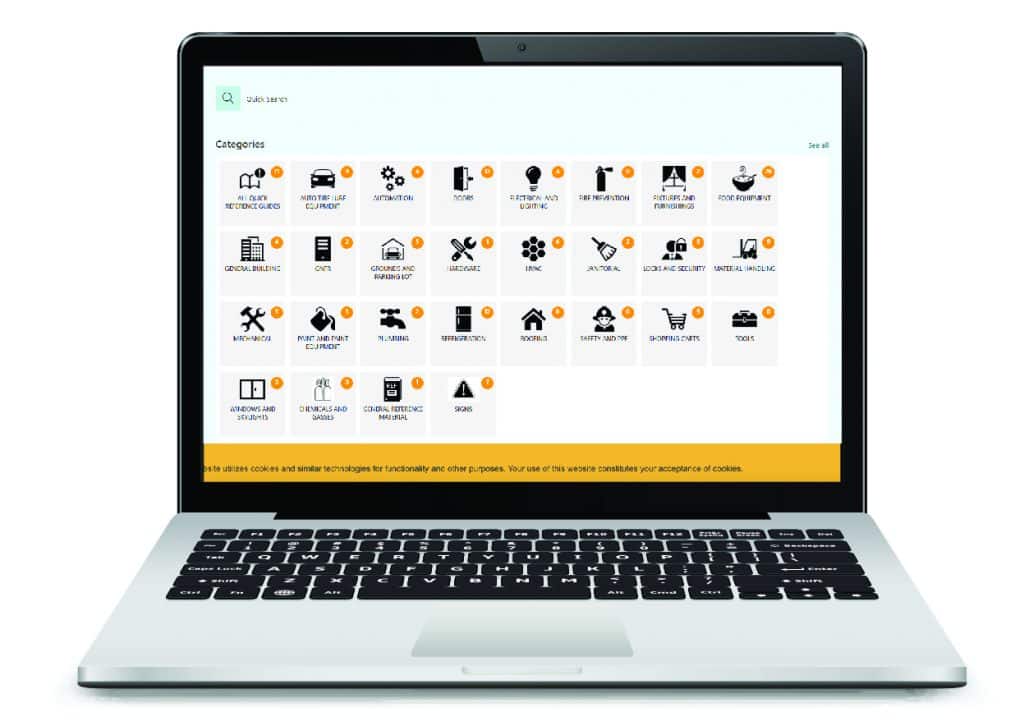

ZEUS is SDI’s cloud-based way to access all tail-spend items and MRO from one point of contact in real-time while processing all transactions into a single, consolidated, itemized bill each reporting period.

Whereas other platforms only give you the framework to do it yourself, SDI deals with ALL of the suppliers and the electronic enablement, so you don’t have to. ZEUS procurement technology is ideal for sites and operations of all sizes. With MRO, visibility and control are crucial, so ZEUS makes it easier to find and get the parts you need ASAP.

Recording accurate data on all equipment, parts, and linking the parts to the correct equipment is a fundamental building block for any Digital Supply Chain Management Program. SDI can create Material Masters (MM) and Bills of Material (BOM) to provide accurate equipment data always in the right location. Our Technical Services engineers can assist your team in developing material data that goes beyond a basic description.

Accurate data is the cornerstone of any maintenance and reliability program. SDI’s Engineering Document Management System, Tech Vault, is cloud-based and accessible in-app or online via login credentials into your SDI program. We’ve optimized this central knowledge hub for easy searchability and viewing on mobile devices, laptops, and tablets. It’s engineered for the way you work.

A central, online living repository with up-to-date curated content, SDI’s Engineering Document Management System – Tech Vault – is invaluable for a long list of practical reasons.

Material creation, updating information, and bill-of-material creation – all in a central, online living repository to drive your operation’s effectiveness.

ZEUS integrates, automates, and digitizes the way customers find, evaluate, work with, and transact with their suppliers. Organizations who make procurement automation a priority as part of an overall digital transformation strategy are able to leverage technologies like AI and RPA to manage spend in real-time, predict demand, and predict sources of future supply in addition to being able to run sourcing events

faster.

Automating the procurement and MRO supply chain process enables sourcing efficiency by codifying processes to ensure the lowest total cost of ownership, considering supply reliability, product quality, innovation, compliance, and other factors in addition to pricing. Establishing machine-driven sourcing decisions delivers quality and efficiency no human could hope to achieve for speed and transparency in ordering, forecasting, maintenance scheduling, and more. Combined with procurement automation, this means sourcing can improve response times, better leverage the market, enable secondary market sourcing, and increase RFQ effectiveness.

Robotic Process Automation provides value-added efficiency enhancements and improves the sourcing experience. Users can simply upload the details of the items they need sourced, and ZEUS will reach out to identify the pool of relevant suppliers and suitable sources. An artificial intelligence layer stack ranks vendors to compare web data to the input data, ensure like for like matches, and prepare pricing for upload. Buyers review and provide post-purchase feedback to continually improve automated categorization and classification of requests.

Automating the search of items across multiple suppliers and obtaining mulitple quotes, ZEUS’s intelligent automated sourcing increases accuracy and improves speed to execution.

Many companies look at the inventory management process from just one point of view. But an effective inventory management solution is holistic in its approach; utilizing top-of-the-line inventory management technology and looking at all possible areas to help cut costs and clean up processes.

Beyond smarter inventory management, you’ll also achieve reduced inventory levels, improved service levels, reduced freight and handling costs, reduced inventory carrying costs, actual lead-time data, and notification of over-utilized and under-utilized parts, all of which results in a lower total cost for your MRO inventory.

We’ll help carefully tighten your storeroom inventory, but we’ll also give you visibility and information at every turn – which gives you incredible control and efficiency regarding your MRO. To prevent stock outs of critical spares and prevent the future growth of Slow moving/obsolete (SLOB) inventory, SDI deploys Predictive Inventory Management. This professional service developed specifically for MRO combines technology, intellectual capital, and management expertise to drive to optimum customer inventory levels while minimizing, even eliminating, future occurrence of obsolete inventories and stock-outs.

SDI is uniquely positioned in the world of MRO integrated supply by having incorporated into its services inventory forecasting capabilities specifically customized for the world of MRO. Utilizing historical data on your daily usage and supply transactions, ZEUS uses 32 different algorithms to apply the best inventory forecast model (i.e., moving average, seasonal trend, low volume) to predict demand. The system also factors in your economic and service level drivers to develop a replenishment plan that indicates what items to order, in what quantity, and in a manner, which will reduce total inventory, decrease transportation and receiving costs and increase service levels.

While the demand signals for MRO may fluctuate, SDI’s digital technology and supply chain services can help you understand your inventory, giving you the tools to take action and change behaviors to drive different procurement activities to avoid supply chain disruption.

Searching, finding, ordering, and tracking parts and repairs doesn’t get any easier or more intuitive than SDI’s MRO system. From intuitive search technology to mobile storeroom and MRO software apps that allow accurate and timely cycle count, issuing, picking and delivery – even a vendor portal for suppliers to enter invoices and acknowledge POs – SDI has all the MRO software and technology in place to keep your entire supply chain well-connected, well-informed, and ultra-efficient. With our MRO software and cataloging technologies, master data management and cross-reference data searching, SDI can add structure, order, and visibility to a typically inefficient scenario.

SDI’s Best-in-Class storeroom assessment tools align to each phase of your MRO service model to help identify process improvements for operating efficiency and enhanced service levels that go beyond cost avoidance and piece-price savings. ZEUS combines an entire portfolio of purpose-built solutions as part of a true 360-degree life-cycle approach to MRO.

To have reliability, manufacturers and maintenance professionals need visibility and control that extends beyond the assets/equipment to the supply chain supporting those assets. The ability to predict a failure is not nearly as powerful as the ability to prevent it by having the parts and materials needed to minimize downtime. That’s why SDI’s developers integrate ZEUS as a plug & play system to connect directly to customer ERP, CMMS, WMS, as well as Supplier and Freight Carrier systems – seamlessly and safely sharing data among internal and external systems.

SDI offers a true plug-&-play solution to integrate for secure and easy passage of data between systems, enabling customers to access cutting edge technology in real time, without having to start over or build it from scratch. APIs also allow for simple integrations between EAM and CMMS systems and between purchasing and ERP systems. This results in greater transparency, improved efficiency, elimination of waste in the process, and speeding the process.

MRO is a pervasive problem for all maintenance organizations and the convergence of FM, SC and EAM are strategic inflection points that will help achieve greater efficiencies and control – ultimately giving companies a competitive edge.