Home » Supply Chain Services » FM Master Data Management

Effective spend management, enabled by automation and catalog management, means low-value/high-volume transactions can be dealt with more efficiently. We start with clean data, including controlled data maintenance for all description changes and new parts, to ensure information integrity. More than just data collection and cleansing, SDI normalizes, enhances and standardizes your catalog data, identifying critical spares, and uncovering additional areas for optimization – truck stock recommendations, item standardization, OEM commercialization.

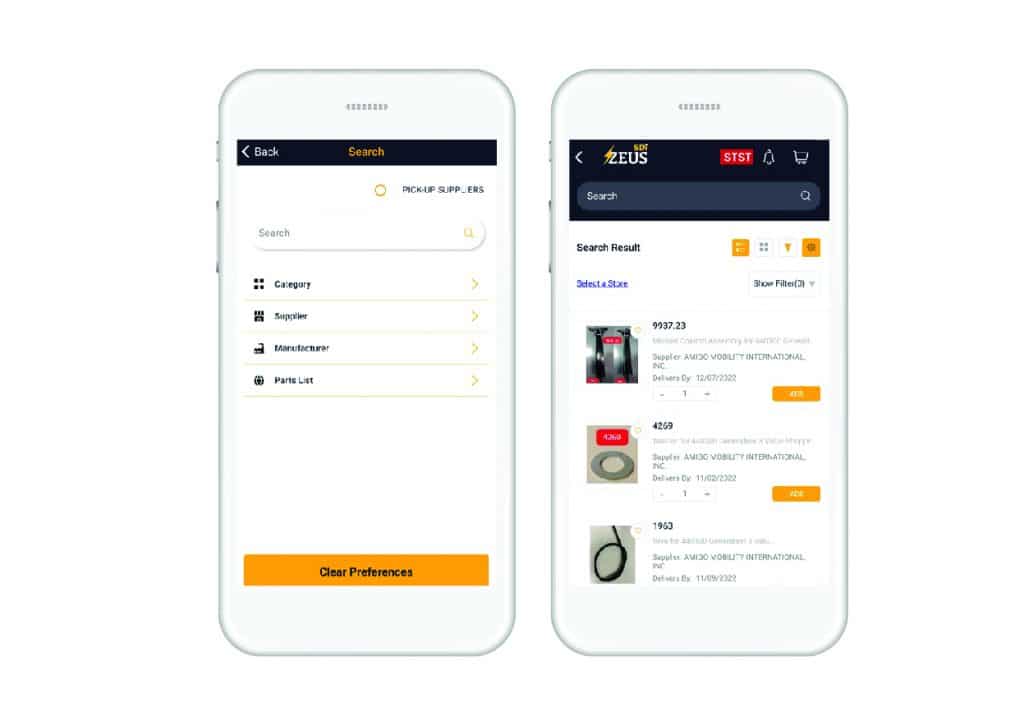

Field technicians can access a single hosted catalog of FM parts, MRO, PPE and essential materials from their truck, home, job site, you name it – all built specifically for your unique business needs. Order everything from general maintenance materials, PPE, HVAC and plumbing to electrical materials. Your catalog can also be configured to include customer-specific OEM suppliers.

As a result of our data normalization and taking your inventory requirements into account, SDI creates a personalized plan to address spend by category, supplier, and manufacturer. SDI sourcing plans are aligned to support your unique objectives.

Your program will include projected savings by category, which sets up a framework for negotiating on your behalf. We’ll also include specific steps to improve the pricing and productivity of existing suppliers within your supply chain.

Relying on purchasing cards leaves you with no actionable data. You can figure out how much you spent with each supplier, but you have no ability to leverage your own spending power.

IPM’s pricing management means more visibility – what store, what asset, what part, what pricing fluctuations – so you can be more strategic with your FM spend and stay ahead of demand.

Your mobile maintenance technicians don’t have time to search through multiple online catalogs or wait for transactions to flow through outdated technology. Techs need the speed and reliability to search based on what’s right in front of them. That’s why IPM’s user-friendly mobile app includes:

When a maintenance work order is raised, technicians experience first-hand how the supply chain impacts downtime on critical assets. Having the right FM parts and supplies to maintain and repair revenue-generating assets and facilities can mean the difference in product sales, possible health or safety issues, and an impact on the in-store customer experience. IPM’s Catalog Management, Inventory Sourcing, and Pricing Management works harder for you, leveraging data-driven insights and deep breadth of FM and MRO category expertise. To learn more, contact us today.

Copyright ©2025 SDI, Inc.