Mountains of data gathered from disparate sources and ERP systems – sometimes overlapping, often overlooked – is daunting. Wrangling that mess, making sense of it, and squeezing out the a-ha insights takes specific tools and specialized expertise to filter out the noise and reveal the actionable intelligence you’ve been missing.

Disruption is unprecedented in today’s global supply chain. Being able to visualize and interpret data on suppliers and service providers, parts and materials, and work orders and asset repairs across your organization gives you the power to de-risk the supply chain while reducing costs and enhancing productivity.

SDI’s Data Analysts specialize in supply chain and have control-tower visibility into the ecosystem that connects our clients’ Enterprise Asset Management, Facilities Management, and Supply Chain Management strategies to optimize how supply chain fits into their workflows related to parts, maintenance, labor, and facility/asset management.

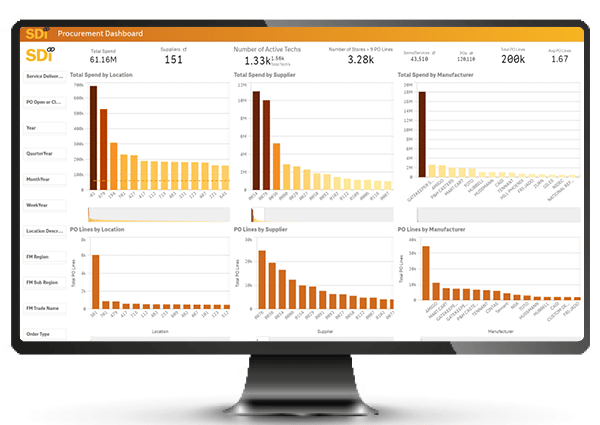

While anyone can buy a data visualization tool to deliver pretty dashboards of pie charts and bar graphs, SDI’s Advanced Data Analytics team brings specialized supply chain expertise for a human-centered design thinking approach that empowers our clients to solve their toughest supply chain challenges and meet their objectives.

Using ZEUS – the game-changing technology purpose-built for the indirect supply chain of FM parts and materials, MRO, PPE, Tailspend, and essential GNFR – SDI’s Data Analysts walk our clients through their data, helping them break away from the tribal knowledge that is typically siloed by function across their enterprise, to reveal the story behind their data.

This holistic view of the supply chain enables better, data-driven decision making, to pinpoint exactly where to implement changes that drive measurable improvements for each client’s specific KPIs.

Draw the connection between parts procurement and facilities/asset performance

Drive action based on data to get ahead of demand and improve the performance of your facilities’ revenue-generating assets.

Aggregate, analyze, distill, and leverage key data and spend information from disparate computerized maintenance management systems, work order management systems, warehouse management systems, and other enterprise resource platforms

Get visibility into spend patterns and trends by supplier, item category, service provider, trade, service category, etc. to develop strategic sourcing strategies and uncover opportunities for improvement

Drill down to facility-level data, location/site level, asset-level data for service time/rate analysis and work order completion rates

More people are being exposed to data during their daily work than ever before, necessitating a shift in the skillset of the workforce. Organizations have become more data savvy as industry has adopted smart facilities and IoT connected assets. Data literacy is essential in the shift for multi-site FM organizations, manufacturing, education and other asset-intensive industries to adopt digital technologies that enable them to thrive in today’s world.

Now more than ever, identifying issues, planning for continuity, preventing overspending, and having a detailed road map to de-risk the supply chain and implement real-world changes is what our customers need to succeed in this digital world.

Read more about how SDI’s advanced data analytics enables better indirect supply chain management — from MRO data and spend analytics and savings projections to speed-to-savings in your sourcing plan, supplier performance management, improvements in your Purchase-to-Pay process and identifying low-hanging fruit throughout your facilities.