Key Takeaways

- Hidden MRO (Maintenance, Repair & Operations) spend often lives inside facilities‑services budgets, unseen and unmanaged.

- Facilities management (FM) vendors may bundle supplies, parts and materials into service contracts—with markups that erode savings potential.

- Data analytics—by integrating CMMS data, general ledger/invoice data and supplier costs—reveals the “blurred line” between FM services and consumable MRO spend.

- With the right tools and supply‑chain expertise (such as SDI’s ZEUS engine), you can benchmark, identify low‑hanging fruit, and redirect spend to optimized channels.

- Implementing this requires structured spend‑data capture, classification, cross‑functional collaboration (operations, procurement, reliability), and a roadmap for ongoing governance.

- FAQ section at the end covers typical questions around visibility, benchmarking, technology and next‑steps.

You likely already recognize that your maintenance team uses spare parts, consumables and materials to keep your assets running. But did you know much of that same consumables spend is often hidden within your facilities‑services budget? Many organizations assume that because the item is “included” via a facilities vendor, it’s required or appropriately procured. In reality, it’s perfectly possible that:

- A service provider includes jan/san supplies, light bulbs, HVAC filters etc. inside a bundled contract.

- Those supplies may carry markup because they are rolled into labor or service fees (rather than negotiated as part of a centralized MRO program).

- The facility services vendor may procure at list prices (or even above-volume discount pricing) and apply margins—introducing cost inefficiencies.

- Because the spend is lumped inside service charges, your procurement, reliability and inventory teams may not have line‑of‑sight into those items.

- That lack of visibility undermines your ability to apply category management, standardization, strategic sourcing, inventory optimization and lifecycle cost control.

From our work at SDI, we’ve observed that this phenomenon is widespread in large portfolios—especially when FM and MRO responsibilities are siloed. When you bridge those silos, you unlock significant savings potential.

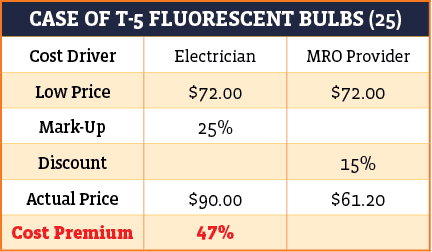

A Simple Example: The Light‑Bulb Case, and Why It Matters

Consider a real world example: A case of 25 T‑5 fluorescent light bulbs. On the surface the item appears trivial. But if you compare:

- Having your FM vendor include the bulbs in a bundled service contract (with markup)

- vs. you sourcing the same bulbs as part of your MRO contract (negotiated volume, standardised part number)

You could see a net price swing of ~47% (when the service provider charges markup) compared to using existing MRO channels. That means across a multi‑site portfolio, dozens of consumables and predictable items—floor wax, toilet paper, filters, light‑bulbs, fasteners—carry a massive drag on cost, quality and control.

Beyond price, there are added benefits when you integrate with your MRO provider: strategic sourcing, inventory management, specification control and fewer non‑standard parts. This gives you better control over product quality (you know what you’re buying) and over cost (you’re not paying hidden mark‑ups).

Where the Spend Hides—and How to Bring It to Light

With our clients, SDI identifies hidden MRO and FM‑embedded spend by analyzing multiple data sources. Key data‑locations include:

- Your CMMS (computerized maintenance management system) and work‑order history, capturing materials used and their cost.

- Your general ledger and disbursements to service providers (facilities vendors, contractors) where “parts & materials” may be embedded in line items.

- Invoice detail from service providers: digging into embedded materials or supplies charges, line by line.

Analyzing these data sources, we can parse what you are spending—and where. With our proprietary analytics engine ZEUS, plus 50+ years of MRO supply‑chain experience, we can clarify the blurred boundaries between FM and MRO. From there we perform benchmarking, identify low‑hanging fruit and deliver savings by redirecting spend to more efficient channels.

How to Build a Roadmap for Capturing Hidden MRO Spend Through FM

Here’s a pragmatic roadmap you can follow:

Step 1: Assemble the cross‑functional team

Include maintenance/reliability, procurement/source‑to‑pay, finance (GL/invoices) and facilities management. Alignment across silos is essential.

Step 2: Define your objectives and baseline

Define what visibility means for your organisation: e.g., “we will reduce FM‑embedded consumables spend by 10 % within 12 months”, or “we will migrate 80 % of facility supplies into our MRO contract”. Secure executive sponsorship.

Step 3: Data collection and cleansing

- Extract CMMS usage/parts data.

- Extract GL/disbursement data to service providers.

- Extract detailed invoice line data from FM vendors.

- Clean and standardise item descriptions, part numbers, units, pricing.

Step 4: Classification and pivot‑analysis

Apply standard taxonomy (e.g., UNSPSC) or your own to categorize consumables, materials, parts, etc. Identify which items are currently being purchased via FM vendors versus those via your MRO channels.

Step 5: Benchmark and identify opportunities

Using tools like ZEUS (or similar analytics engines) you can benchmark your unit‑pricing, supplier mix, and purchase categories. Identify items where you see: high price variance across sites, frequently purchased consumables, or items above threshold that could be centralized.

Step 6: Re‑source or migrate spend

For identified items, migrate procurement from FM vendors into your MRO program: renegotiate supply contracts, standardize specs, consolidate suppliers, and align with your supply‑chain partners.

Step 7: Implement control and governance

- Set rules: e.g., “all replacement filters must be purchased via approved MRO catalogue”.

- Monitor FM vendor invoices for embedded consumables and hold them accountable for transparency.

- Measure key metrics: spend reduction, tunnelled cost, inventory reduction, downtime impact.

Step 8: Continuous review and optimization

Spend analytics isn’t one‑and‑done. Establish periodic review cycles, refine classification and expand scope to additional categories.

Why SDI’s Approach (and ZEUS) Gives You an Edge

Here’s how partnering with SDI (and leveraging the ZEUS analytics engine) positions you differently from generic providers or FM vendors:

- Decades of MRO supply‑chain experience: SDI has over 50 years of experience helping asset‑intensive enterprises manage indirect/MRO spend effectively.

- Integrated analytics and platform: ZEUS brings together spend data, sourcing intelligence and benchmarking to deliver insights into hidden FM‑embedded spend.

- End‑to‑end supply‑chain services: From procurement, inventory, storeroom management, through to reliability and master‑data services.

- Tailored for the MRO‑/FM interface: Many FM vendors stop at facility labor; SDI treats parts, consumables and storeroom operations as part of the broader MRO ecosystem.

- Action‑oriented roadmap and governance: It’s not merely data; it’s data + supply‑chain strategy + implementation.

In other words, SDI doesn’t just reveal where you’re overspending—it helps you re‑engineer the supply‑chain so you consistently capture those savings.

Key Benefits You Should Expect

By credibly implementing this approach, you should expect outcomes such as:

- Reduced cost per consumable (via negotiated volumes, standardisation).

- Better visibility into FM‑embedded spend (so fewer “surprise” invoices).

- Increased wrench‑time for maintenance staff (less time chasing parts or sourcing non‑standard items).

- Lower inventory carrying cost and fewer redundant SKUs.

- Stronger supplier relationships and better contract terms.

- Improved asset‑uptime (due to availability of correct parts and fewer emergency purchases).

- Enhanced governance, auditability and compliance of indirect/MRO spend.

And when leveraged across multisite portfolios, the cumulative savings become meaningful.

FAQ – Frequently Asked Questions

What exactly is “hidden” MRO spend?

Hidden MRO spend refers to consumables, parts and materials that technically belong in the MRO budget (maintenance, reliability, storeroom) but are instead being procured or charged via facilities‑services vendors or bundled into FM contracts—often without proper classification, oversight or procurement optimization.

Why can’t I just rely on my FM vendor to procure everything?

While bundling everything into the FM contract may look convenient, you lose control over specification, standardization, procurement leverage and transparency. FM vendors may procure at list price or apply mark‑ups, may not track consumable replacement usage rigorously, and you lose visibility into categories that should be managed via your MRO ecosystem.

How much effort is required to pull this off?

It varies by organization. Key efforts include data‑extraction (CMMS, GL, invoices), data cleansing/classification, cross‑functional alignment, and supplier/part‑migration. With the right platform and supply‑chain partner (e.g., SDI + ZEUS) the process becomes much more manageable.

What types of items should I focus on first?

Good “low‑hanging fruit” includes high-volume consumables (filters, light bulbs, jan/san supplies, fasteners), items with consistent usage across sites, items purchased outside your negotiated MRO catalogue, and items that exhibit price variance between sites or vendors.

How do we measure success?

Typical metrics include: percentage of spend migrated from FM‑vendors to MRO contracts; cost reduction per item/consumable; reduction in SKU count; reduction in inventory carrying cost; improvement in parts availability; and reduction in wrench‑time lost chasing parts/supplies.

What’s a realistic timeframe to see meaningful savings?

Often you can start seeing meaningful savings within 3‑6 months (from initial cleanse and classification to first migrations). Full rollout across multi‑sites may take 9‑18 months, depending on complexity.

In today’s competitive and asset‑intensive environments, overlooking hidden MRO spend inside facilities‑services budgets is a missed opportunity. By leveraging advanced data‑analytics, standardized classification, and supply‑chain expertise (such as that offered by SDI and ZEUS), organizations can bring that invisible spend into the light—generate significant savings, improve control, optimize inventory, and fundamentally shift the maintenance/operations paradigm from reactive cost‑center to strategic value‑driver.

If you’re ready to take back control of your MRO spend—especially as it lives within your FM sphere—reach out to SDI today and let us help you unlock hidden savings and operational advantage.