Home » Supply Chain Services » Integrated Parts Management » FM Source to Pay

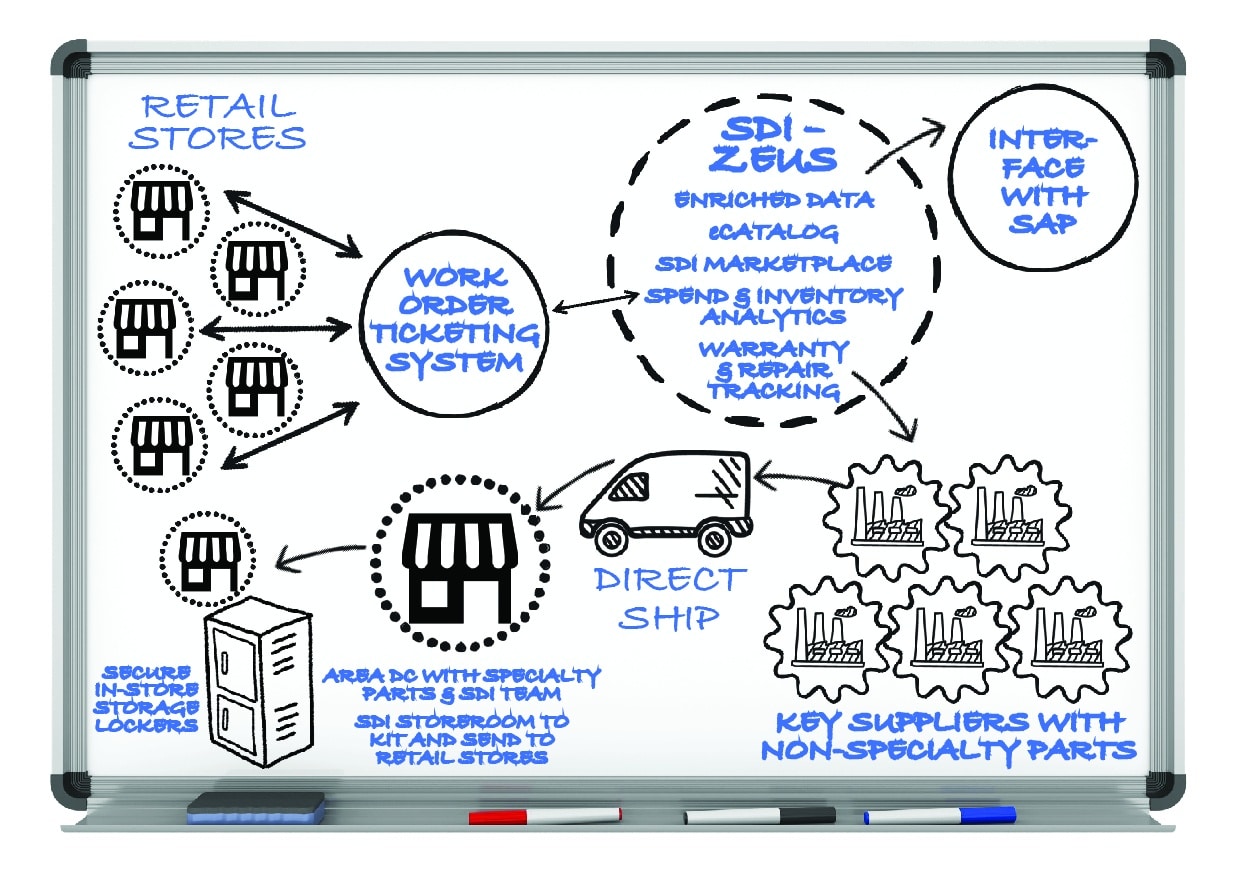

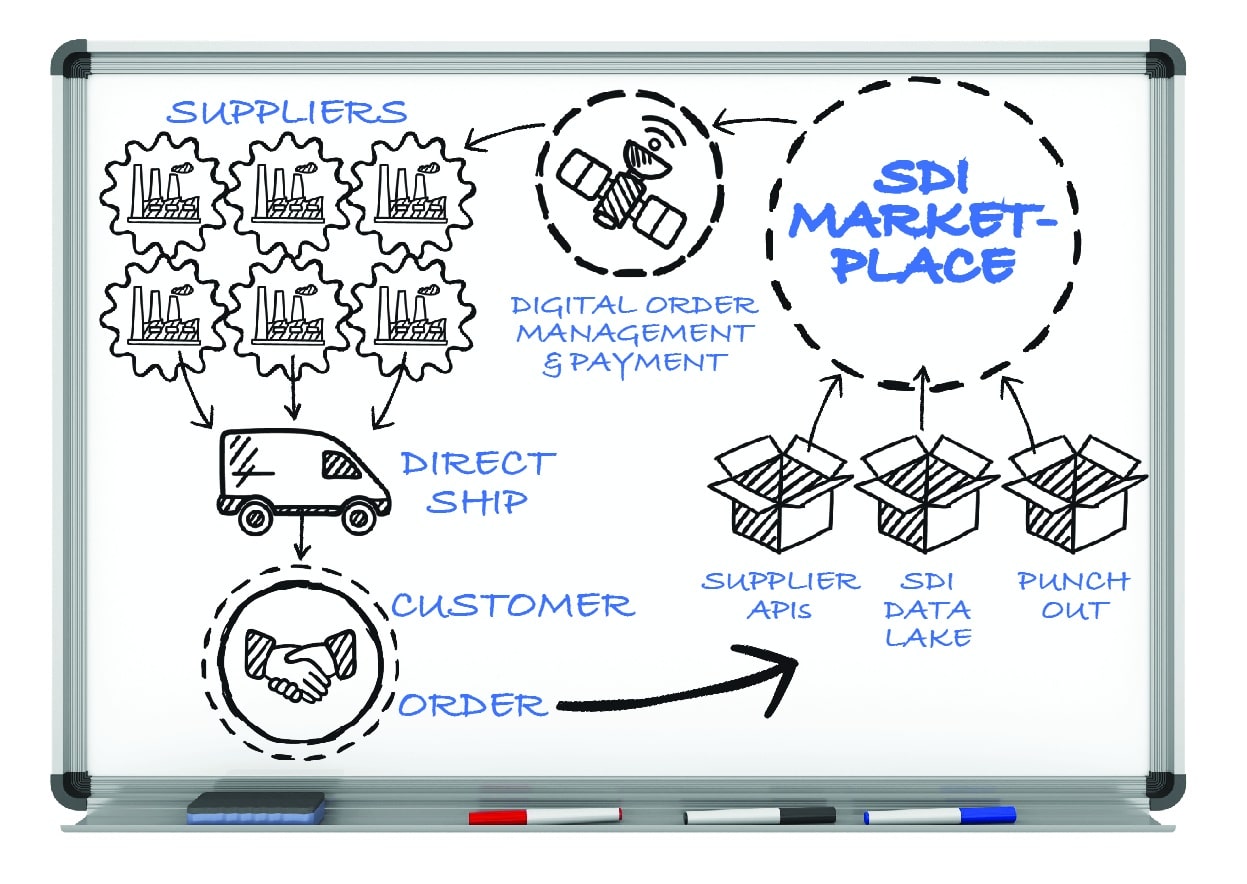

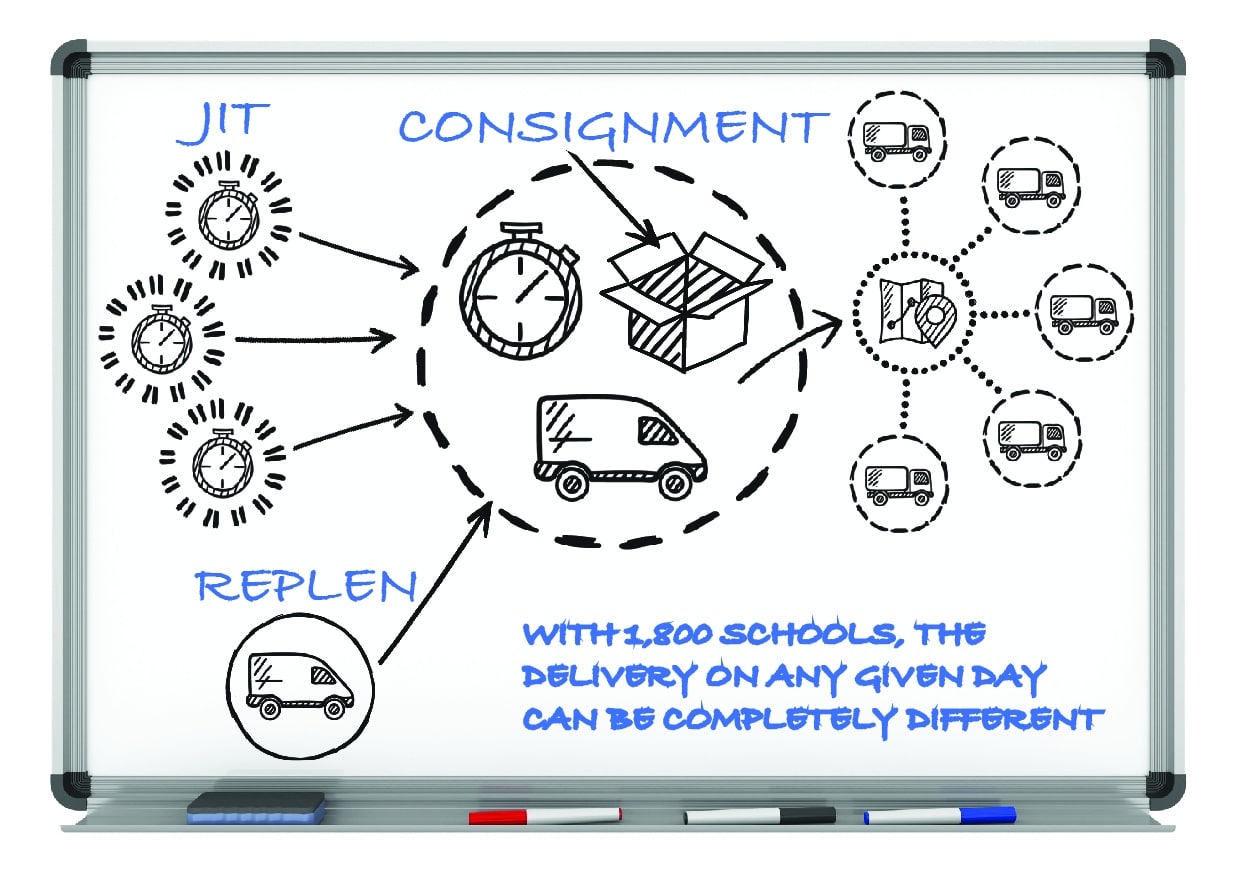

SDI works with you to design, build, and operate the fulfillment model that works best for your distribution needs – variable-destination work order fulfillment, fixed-destination milk runs, procure-to-drop ship models. We collaborate with your teams, for a deeper understanding of your supply chain to enable you with omnichannel fulfillment solutions like integrated supplier ordering assistance; local will-call pick up; and electronic pick-pack, routing and delivery systems — that provide real-time visibility into order and delivery status for enterprise-wide efficiency and control.

In the typical ordering process for a store or field technician, the tech would identify the parts they need, relying on memory, and then head to the local supply house. If they couldn’t find what they needed, they’d start calling suppliers or searching the internet. Then they’d purchase it on an account or with a credit card or purchasing card (P-Card). This process meant additional lost repair time spent on-line at suppliers, on the phone or driving from location to location to find the needed parts, often not able to get them all locally which pushed job completion off until parts arrived anyway.

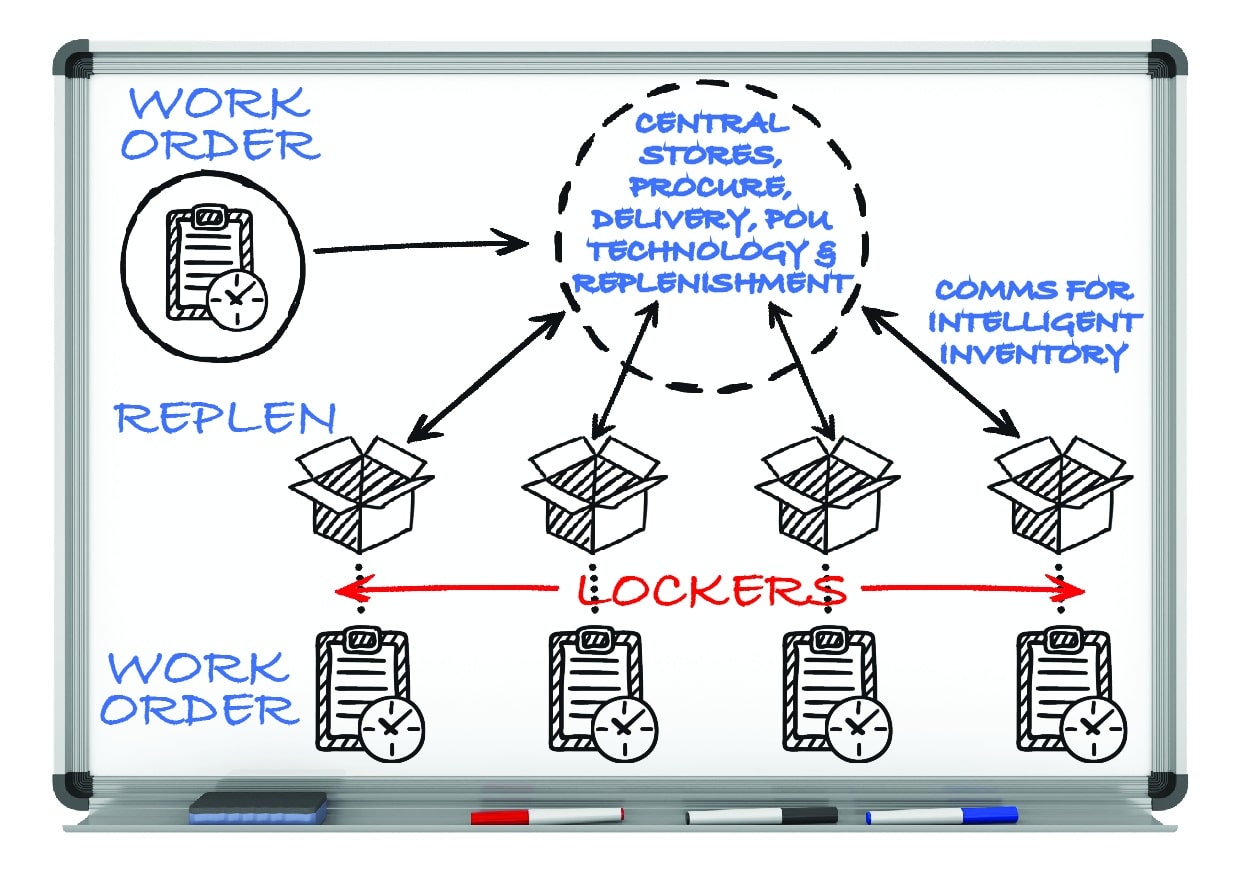

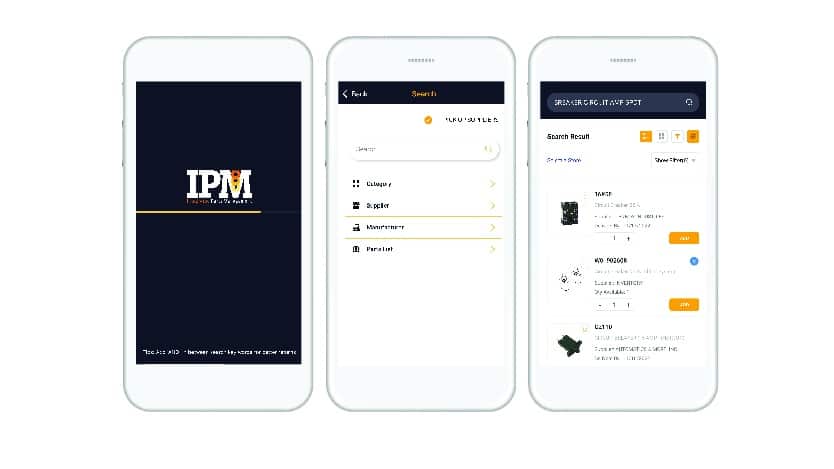

In an Integrated Parts Management program, the field techs use a single mobile app to order many of the common items they need. They use this same app to place non-catalog items as well. They can upload photos of the part, equipment name plates, etc for any items they need, all while standing right in front of the equipment on the job site.

Often the technicians, who have multiple open work orders at multiple facilities, have little to no visibility on which items have arrived at which site, without actually making a trip to the site to verify. SDI’s IPM program places that order tracking right in the mobile app so technicians can better plan their work schedules and reduce the travel time

SDI’s Integrated Parts Management solution offers a Technical Parts Support Team that is comprised of part-sourcing experts with trade experience and technical backgrounds, allowing for understanding of the equipment and systems associated with the facilities maintenance trades. This team communicates with the field, speaking their “language” and using their experience to help technicians solve the challenges they may be experiencing in locating parts for their work orders.

The Parts Team also helps to act as a translator to explain to non-technical groups how or why additional items may be needed, what an item is, or how it works. The Parts Team works to collect as much technical information (operator manuals, maintenance manuals, parts manuals, service bulletins, reference guide, spec sheets, training & service instructional videos, etc.) from various sources and place this information in a searchable access point available at the Tech’s finger tips directly from the mobile app.

a data-driven, digital supply chain allows you the transparency across your entire supply chain ecosystem to respond more quickly to demand and better identify savings opportunities.

deep breadth of MRO and FM parts category expertise and frequency in the market means you benefit from the market intelligence and specialization to get more spend under your control.

beyond identifying opportunities for improvement, SDI’s supplier management drives compliance to negotiated pricing and service contracts so you REALIZE the savings and performance improvements that matter to you –and better direct spend towards the suppliers who align with your corporate social responsibility and environmental social governance goals.

Copyright ©2024 SDI, Inc.